QINGGONG’s steel welding shot blasting machine features:

Type | unit | QGX600 | QGX1200 | QGX1200 | QGX1500 | QGX1800 |

Effective blasting width | mm | 600 | 1200 | 1200 | 1500 | 1800 |

Dimension of entrance(W×H) | mm | 800×1400 | 1400×1600 | 1400×2000 | 1700×1600 | 2000×1700 |

Work speed to achieve a cleaning of Sa2.5 ISO8501 | m/min | 0.5~3 | 0.5~3 | 0.5~3 | 0.5~3 | 0.5~3 |

Number of wheels×power | kW | 8×7.5/11 | 8×11/15 | 8×11/15 | 8×11/15/18.5 | 8×11/15 |

Wheel optional | kW | — | — | 10×11/15 | 10×11/15/18.5 | 10×11/15/18.5 |

Abrasive initial filling capacity | kg | 4000 | 4000 | 4000 | 4500 | 8000 |

Processed length of work piece | mm | 1200~12000 | 1200~6000 | 1200~12000 | 3000~12000 | 2400~12000 |

Foundation pit required |

| Yes | Yes/No | Yes/No | Yes | Yes |

Conveying system:

Component: rollers, chain, reducer, sprocket cover, and roller support.

1. Roller is first welding and then processing, to ensure the concentricity of the roller

2. The material of roller is 45# carbon steel, it can use 8-10 years.

3. Both sides of the roller are equipped with sprocket covers to protect the sprockets and spindle nose.

4. The roller support has secondary reinforcement, it enough to load the workpiece.

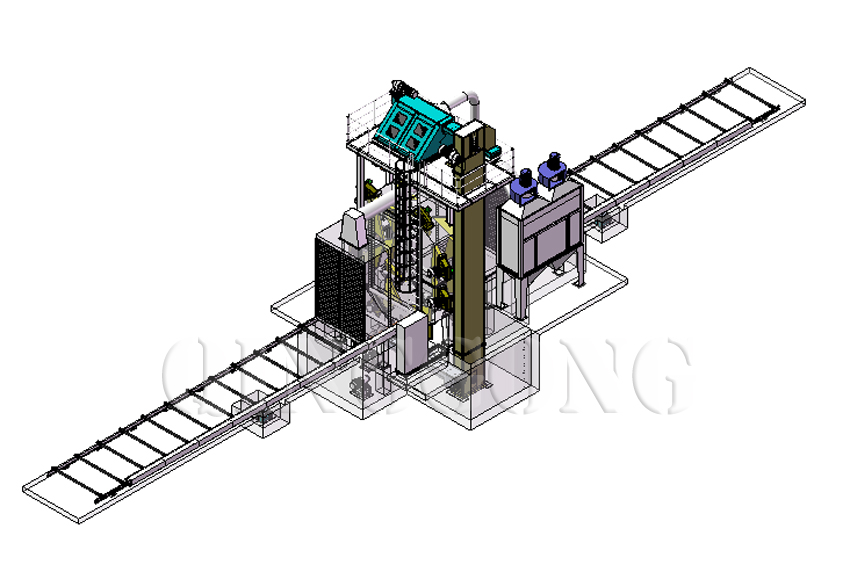

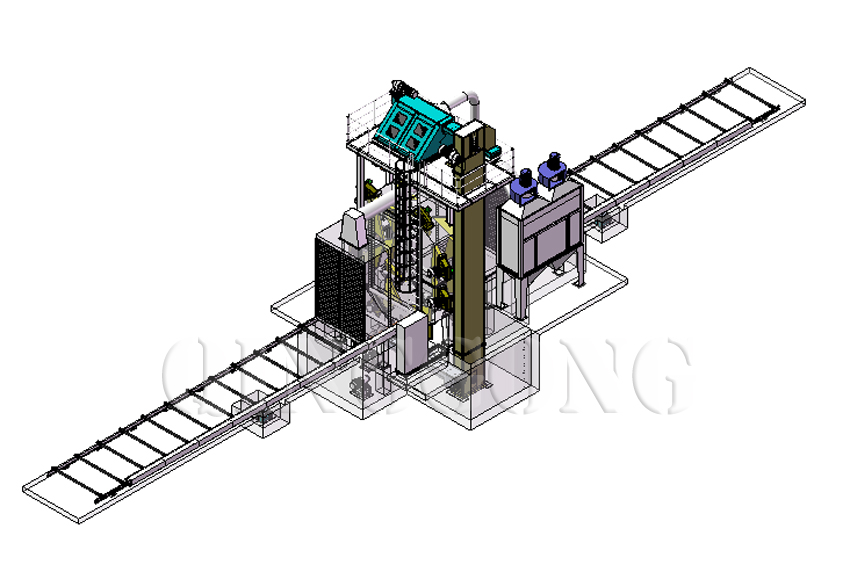

Blasting Chamber:

Steel plate shot blasting machine’s chamber component: shot blasting chamber, front and rear sealing room, sand-guide channel and others.

1. The engineer team use 3-D dynamic simulation design blast turbines layout to ensure that the steel shot ray can cover the surface of the workpiece 360 degrees.

2. Shot blasting chamber with ZGMn13 steel guard plate, long service life.

3. Six layers protection curtain to prevent the shot balls spatter out during blast cleaning. The curtain layers is natural rubber material with leaf spring which can automatic reset, ensure the sealing of the machine.

4. High chrome wear resistant cast iron grate guard plate which protect the screw conveyor and prevent big clump to get into the hopper damaging the bottom screw conveyor.

Abrasive recovery system:

H beams shot blasting machine system use a longitudinal screw conveyor to reclaim the used blasting media and contaminants into the crosswise screw conveyor, then into the bucket elevator and abrasive residue separator, and then the cleaned abrasive get into the storage hopper to recycle, the residual will get out of the recycle system from the air wash cleaner system.

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro