When it comes to the construction industry, the importance of maintaining clean and rust-free steel surfaces cannot be emphasized enough. Whether it's prepping steel beams for welding, surface preparation for coating or welding, or simply removing layers of paint and rust, utilizing an efficient and reliable equipment becomes crucial. In this blog, we will explore the benefits and applications of a belt shot blasting machine in achieving superior results in the removal of paint and rust from steel surfaces in the construction industry.

The Need for Effective Surface Preparation

In the construction industry, steel surfaces often suffer from layers of paint and rust, hindering the efficacy of subsequent processes such as painting, coating, or welding. To guarantee secure and long-lasting structures, it becomes essential to address these issues through proficient surface preparation methods. This is where a belt shot blasting machine emerges as the go-to solution.

The Belt Shot Blasting Machine: Unleashing its Potential

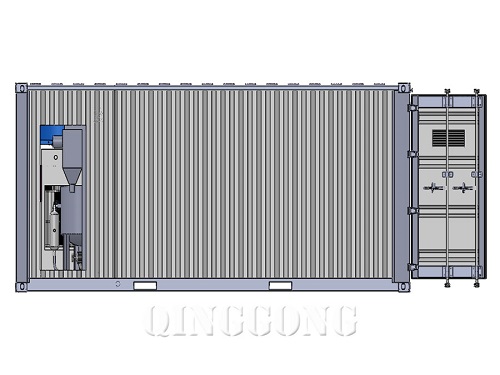

The belt shot blasting machine is a mechanical device that utilizes centrifugal force and abrasive particles to clean and remove paint and rust from steel surfaces. Unlike traditional methods like manual scraping or chemical solutions, a belt shot blasting machine offers a more efficient, time-saving, and cost-effective approach. Its continuous operation on a conveyor system ensures a consistent cleaning process, achieving desired results throughout large-scale projects.

Applications of Belt Shot Blasting Machine in the Construction Industry

From bridges and highways to industrial facilities and oil rigs, the belt shot blasting machine finds its applications across a wide range of construction projects. Its ability to effectively remove paint and rust from steel surfaces makes it indispensable in tasks like preparing steel beams for welding, surface cleaning before coating, and even during the manufacturing process of steel structures. The belt shot blasting machine ensures enhanced surface adhesion, thus contributing to the overall quality and durability of the completed structures.

Benefits of Belt Shot Blasting Machine for Paint and Rust Removal

Increased Efficiency: The continuous operation of a belt shot blasting machine leads to enhanced productivity and reduced labor costs. Its automated process ensures an optimized workflow, allowing operators to focus on other vital aspects of the project.

Environmentally Friendly: Unlike chemical cleaning methods or manual scraping, a belt shot blasting machine eliminates the need for harmful chemicals and minimizes waste generation. By relying on abrasive particles, it provides an eco-friendly approach to surface cleaning and preparation.

Versatility: Belt shot blasting machines can handle a variety of surfaces and materials. Whether it's steel beams, structural members, or other metal components, the machine adjusts to accommodate different shapes, sizes, and types of surfaces, making it a versatile choice for construction projects of all scales.

Superior Surface Preparation: With its high-speed operation and rotating belts, the belt shot blasting machine ensures a meticulous cleaning process. By removing paint, rust, and other contaminants completely, it guarantees an optimal surface for subsequent processes, such as painting, coating, or welding.

In conclusion, the belt shot blasting machine has revolutionized the way surface preparation is conducted in the construction industry. Its ability to efficiently remove paint and rust from steel surfaces not only improves the overall quality and durability of structures but also enhances productivity, reduces labor costs, and promotes environmentally friendly practices. If you're involved in the construction industry and looking for a reliable and efficient solution for surface cleaning and preparation, the belt shot blasting machine is a must-have equipment.

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro