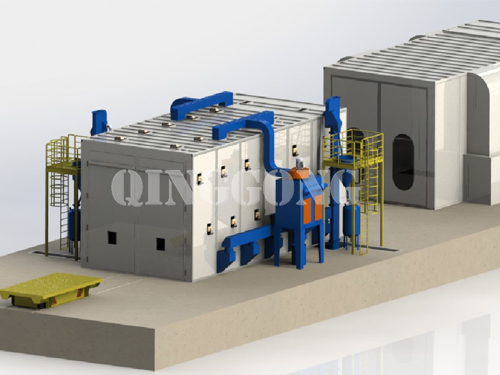

As you know that the recovery system is very important part for shot blasting machine and the recovery system is consist of screw conveyor system, elevator system, separate system and abrasive control system.

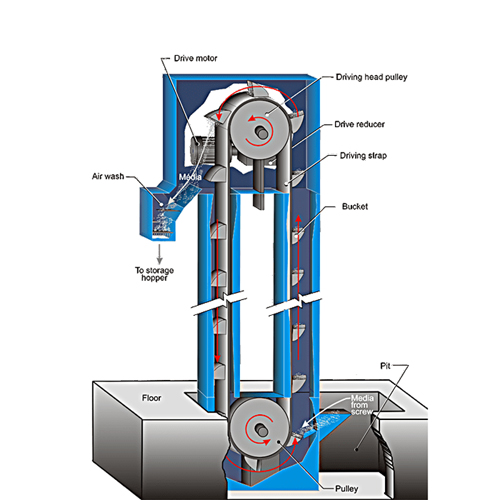

Bucket elevator is also very important part for blast recovery system, so we will introduce the bucket elevator and how is the bucket elevator doing work for the shot blasting machine.

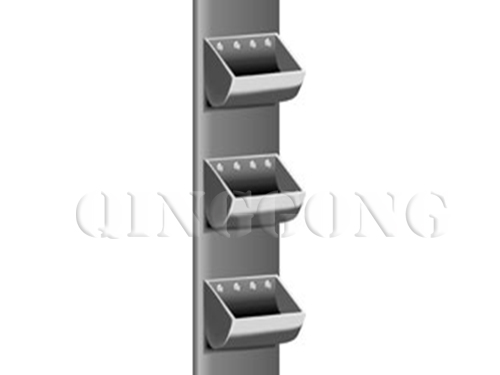

Bucket elevator is composed of cycloidal pin gear reducer, upper and lower roller, transmission belt, bucket, closed abrasive storage hopper and tensioner. The feed port of the bucket elevator is connected with the crosswise screw conveyor, and the discharge port is connected with the screw roller sieve of the separator. In order to ensure that the belt conveyor does not skid on the surface of the drum during the bucket elevator works, the roller surface is welded with steel plates into a cage shape.

How is the bucket elevator doing work?

When the screw conveyor finish collect the abrasive, the next is all the abrasive will be into the bucket elevator. But how is the bucket elevator doing work in the shot blast machine?The abrasive dropped to the separator at the force of gravity In the process of working, the hopper in the transport belt brings the abrasives from the bottom, and drop at the gravity. Using polyester transport belt, squirrel cage roller, intermediate slightly protruding, which not only improves the lifting friction between the belt and pulley, avoiding the old light pulley slippage, but also reduces the lifting belt pretension force, extending the life of lifting tape. And can prevent the projectile stuck in between the lower pulley and the belt so the belt deviation phenomenon, flowing from the projectile between the spokes and the belt. Bottom shaft on the lifting having pulse wheel, can detect the tracking work status. Hoist not turn once or slippage failure, timely feedback signals to the PLC process alarms to ensure the safe operation of the equipment.

Advantages of Bucket Elevator

The vertical design of bucket elevators allows them to handle large volumes of material swiftly and effectively, making them indispensable in high-demand shot blasting environments. Furthermore, their robust construction and ability to minimize wear and tear ensure long-lasting performance and reduced maintenance costs, making them a cost-effective solution for material handling in shot blasting operations. Here are the key benefits in detail:

1. Efficient Material Handling

Bucket elevators efficiently transport abrasive materials, such as steel shot or grit, from the blasting chamber to the separator. Their vertical design allows for continuous and rapid movement of materials, reducing downtime and increasing overall productivity.

2. Space Saving

Due to their vertical orientation, bucket elevators occupy minimal floor space compared to horizontal conveyors. This compact design is particularly advantageous in facilities where space is limited, allowing for better utilization of available workspace.

3. Reduced Wear and Tear

Bucket elevators are designed to handle abrasive materials with minimal wear and tear. The buckets and belts are typically made from durable materials that resist abrasion, ensuring a longer service life and reducing maintenance costs.

4. Consistent and Controlled Flow

The design of bucket elevators ensures a consistent and controlled flow of materials. This reliability is crucial in shot blasting operations, as it ensures a steady supply of abrasives to the blasting wheel, resulting in uniform cleaning and surface preparation.

5. Energy Efficiency

Bucket elevators are energy-efficient, requiring less power to lift materials vertically compared to the energy required for horizontal conveying over long distances. This efficiency translates to lower operational costs and reduced environmental impact.

6. Versatility

Bucket elevators can handle a wide range of materials and are adaptable to different operational requirements. They can be customized in terms of height, capacity, and bucket design to suit specific shot blasting machine configurations and material characteristics.

FAQs about Bucket Elevator

1. What safety measures should be in place when operating a bucket elevator?

Safety measures include installing safety guards, emergency stop controls, regular safety training for operators, and routine safety inspections. Ensuring that the elevator is operated within its design limits and that maintenance is performed regularly can also prevent accidents and ensure safe operation.

2.What is the maximum height for a bucket elevator?

The maximum height of a bucket elevator depends on its design and the material being transported. Typical bucket elevators can reach heights of 100 feet (30 meters) or more. Custom designs can achieve even greater heights if required.

3. Can bucket elevators be customized?

Yes, bucket elevators can be customized to meet specific application requirements. Customizations can include different bucket designs, specialized materials of construction, varying belt or chain types, and additional features like dust containment systems or explosion-proof components.

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro