In May 2021, QINGGONG Machinery has successfully accepted a shot blasting and painting line at our customer site. Let me give a brief introduction of this product.

The process of preservation line refers to the process in which steel is shot blasted to remove rust and coated with a protective primer before processing (that is, the state of the raw material). The pretreatment of steel can improve the corrosion resistance of mechanical products and metal components, improve the fatigue resistance of steel, and extend its service life; at the same time, it can also optimize the state of steel surface crafting, which is conducive to CNC cutting machine blanking and precision blanking. In addition, because the steel shape is relatively regular before processing, it is conducive to mechanical rust removal and automatic paint spraying. Therefore, the use of steel pretreatment can greatly improve the efficiency of the cleaning work and reduce the labor intensity of the cleaning work and the pollution to the environment.

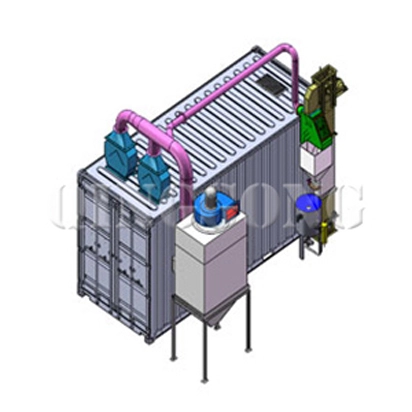

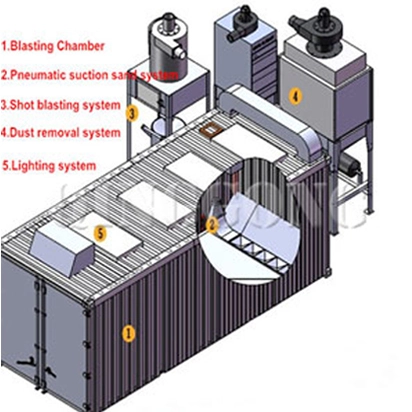

The preservation line is mainly composed of 8 parts, they are inlet and outlet roller conveyor system, shot blasting system, abrasive clean up system, paint spray system, drying and heating system, dust collector system, paint mist treatment system, and electric control system.

Our customer needs shot blasting and spray painting of steel pipes and section sandblasting beams, the max dimensions for workpieces is 2500*700. So our engineering team designs the opening size is 2700*900. In order to promise the shot blasting effectiveness and effectiveness, we provide 12 high-efficiency wheel blast turbines, the power of each turbine is 15kw. The shot blasting system is controlled by Omron PLC, automatically achieve the abrasive supply and reclaim.

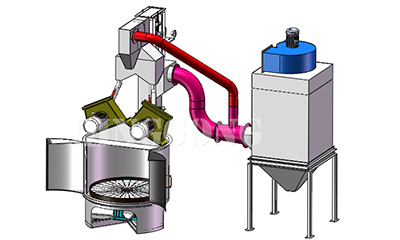

The function of an abrasive clean-up system is to remove the abrasive and containment on the surface of the steel plate after shot blasting. It includes an abrasive collect screw conveyor, nylon brush, height adjust system, and blower fan.

The upper and lower spray bridges in QINGGONG’s high-performance systems are often equipped with 4 spray nozzles each in order to cover a wide spray zone. The spray bridges can move up to 2m/s, brake at the deviating point, and accelerate back in the other direction, often 24 hours a day.

The preserved steel plates and profiles are dried continuously here. The drying chamber can be heated by the exhaust air from the pre-heater so that even paints with long drying times (such as water-based paints) can be dried quickly. Additional circulation of high quantities of air accelerates the drying process. If a pre-heater does not need to be operated all year round, you can also use a self-sufficient heating system as an alternative or addition.

We use a 2-level dust collector: settling chamber and cartridge filters. Cleaning efficiency is up to 99.5%. The filter material from Donaldson, effective filtration area of each filter is up to 15 m³. An air shock valve with a timing device can clean filters regularly.

If you want to get to know more details about this machine, you can check this news for reference: https://www.shotblastpro.com/what-is-shot-blasting-and-painting-line.html

Working video: https://youtu.be/_esUALbFZ0I

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro