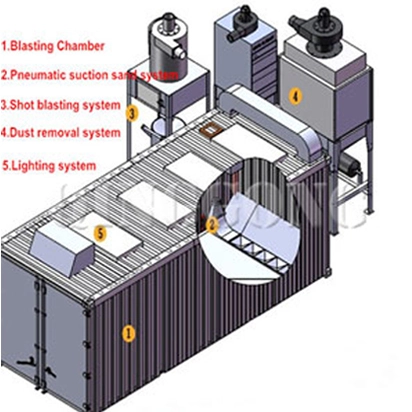

Qinggong Machinery has shipped a set of roller conveyor shot blasting machine to our Colombian customer. The customer mainly used to clean H beams, steel channel, steel angle and some other weldment parts. So according to the detailed parameters, which is provided by the customer. Our engineering team give them the conveyor blasting machine opening size is 1000mm wide and 800mm height, with 4 blast turbines roller conveyor shot blasting machine.

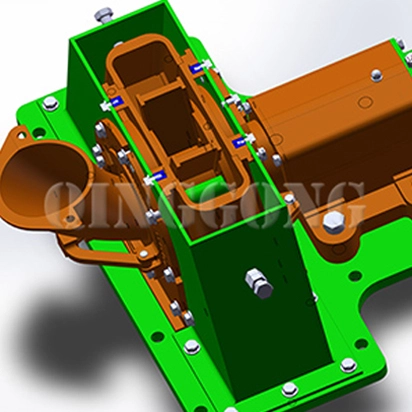

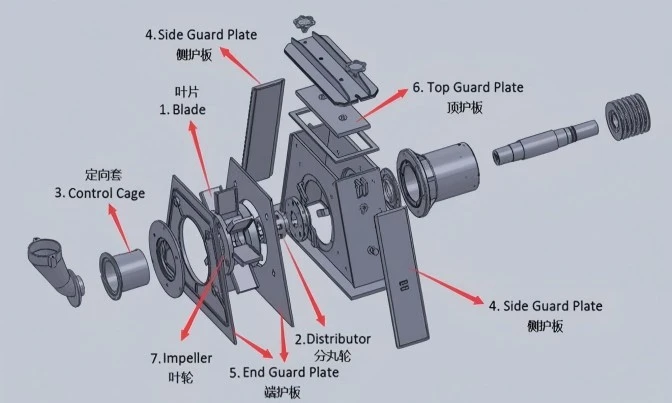

The roller conveyor shot blasting machine has six mainly parts, including roller conveyor system, blasting turbines, blasting chamber, dust collector, recycle system and electric control system. Although each parts are looks like simple, in each part have the very important components which composed of the shot blasting machine. First is the roller conveyor system, it divided into inlet roller table and outlet roller table. On the inlet roller it has a special part -- the photoelectric detection system. When the workpiece on the inlet roller and reach the inlet chamber, the system will send a signal to the computer the workpiece will enter into the blasting chamber and the blasting turbines need to start to work. It can avoid the blasting turbines working when there is no workpiece in the blasting chamber. This system looks smaller but it is the eyes of the shot blasting machine. As we all know the blasting turbines is the core of the industrial shot blasting equipment. Qinggong Machinery blast turbines adopt to the Germany technology to made, which have uniform projection, wide scattering surface and long service life. Blasting chamber have three parts, inlet chamber, blasting chamber and outlet chamber. On the gate of the inlet and outlet chamber all have three-layer rubber belt to cover, the purpose is that to prevent the steel shot splash out of the chamber when the machine is working. In blasting chamber it covered with high manganese steel as the guard plate to protect the chamber to use at least 8 years. The dust collector is the important part to protect environment, which have some cartridge filters in it. Qinggong Machinery used cartridge filter adopt to the Donaldson Technology, the filtering area can up to 15㎡. The filter with the air shock method the cleaning efficiency can up to 99.5%. The recycle system as its name can recycle the steel shots in the whole machine, so that can make the machine continue to work. The screw conveyor makes by the wear-resistant steel and design a saddle type screen on it to prevent some small parts fall into it. The elevator adopts a flat belt drive hopper, the hoppers are made of wear-resistant steel. There are also have check windows for easy maintenance. On the top of the elevator it has a tensioning device, which can easily adjust the belt tightness. Anti-reverse mechanism to prevent the belt from reversing due to power outages and other reasons. After the steel shot into the separator, it will form a waterfall-shaped abrasive flow curtain. Under the full curtain state, the principle of gravity winnowing is used to effectively separate the projectiles from the metal oxide scale fragments, broken projectiles and dust. The machine electric control system with customized PLC control system can automatically control the machine through it. All electric components adopt to the 1-class brand.

Qinggong Machinery as a professional shot blasting machine and sandblasting room manufacturer with 47-years of experience and history, quality is the most important thing for us to get survive for a long time. If you are interested in shot blasting machine and sandblasting room please do not hesitate to contact me.

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro