Qinggong adopt high efficiency blast wheel and 3D simulation design, blast wheel can emit high speed abrasive stream with max velocity up to 85m/s, multiple blast wheels are installed around the blasting chamber, all surfaces can be reached. Roller conveyor transportation system has a stepless speed adjusting function, conveying speed can be adjusted according to dimension and quantity of work-pieces.

Round component shot blasting machine parameter:

Type | unit | QGB600 | QGB1000G | QGB1500 | QGB2000 | QGB2500 | QGB3000 |

Effective blasting width | mm | 600 | 1000 | 1500 | 2000 | 2500 | 3000 |

Dimension of entrance(W×H) | mm | 800×550 | 1200×550 | 1700×550 | 2200×550 | 2700×550 | 3200×550 |

Work speed to achieve a cleaning of Sa2.5 ISO8501 | m/min | 0.5~3 | 0.5~3 | 0.5~3 | 0.5~3 | 0.5~3 | 0.5~3 |

Number of wheels×power | kW | 4×7.5/11 | 4×11/15 | 4×11/15 | 6×11/15 | 8×11/15 | 8×11/15 |

Wheel optional | kW | — | — | — | 4×15 | 6×15/18.5 | 6×15/18.5 |

Abrasive initial filling capacity | kg | 2000 | 4000 | 4000 | 4500 | 6000 | 6000 |

Processed length of work piece | mm | 1200~12000 | 1200~6000 | 1200~12000 | 3000~12000 | 2400~12000 | 3000~18000 |

Foundation pit required |

| No | No | No | Yes | Yes | Yes |

QINGGONG's round component shot blasting machine features:

Blasting chamber:

Working principle

The engineering team uses 3-D dynamic simulation design blast turbines layout to ensure that the steel shot ray can cover the surface of the workpiece 360 degrees.

10 Years Warranty

Shot blasting chamber with Mn13 steel guard plate which has high impact toughness and high service life, fully realize the reflection funcation of abrasive and improve the cleaning quality.

That we promise 10 years maintenance-free warranty to blasting chamber.

High sealing performance

3+ layers of sealing curtain in inlet, outlet opening and between chambers. The curtain layers are natural rubber material with leaf spring which can automaticlly reset,

that prevent the abrasive spatter out duing the blasting and ensure the safe.

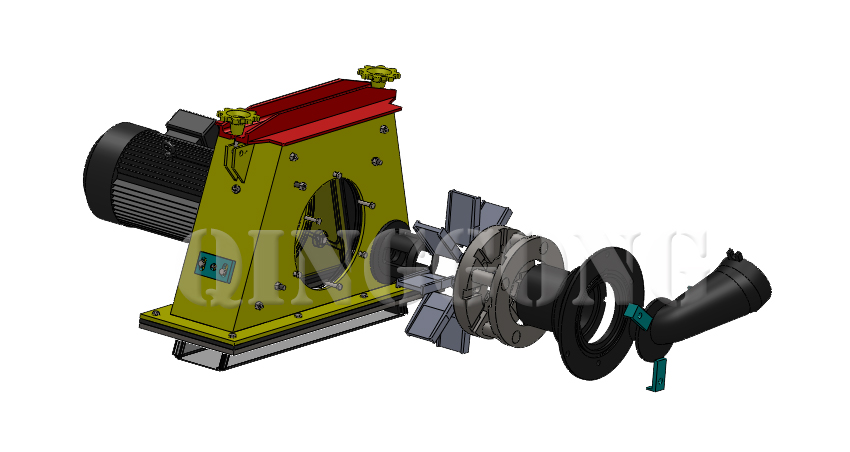

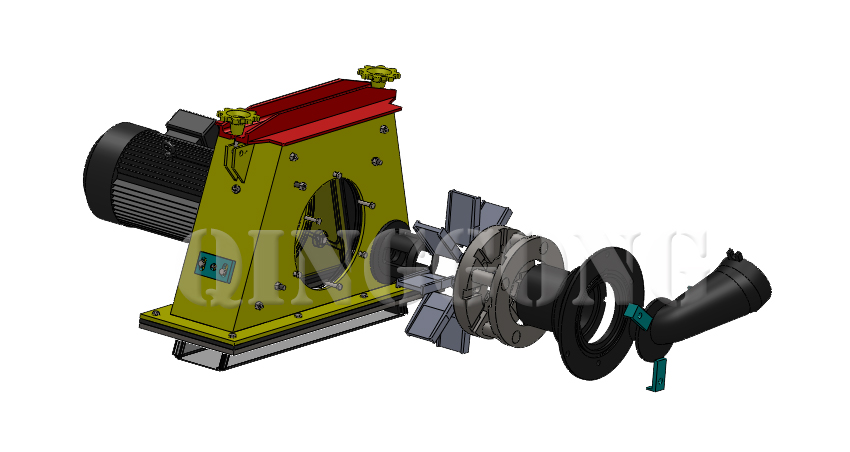

Blast wheel:

The liners form a round track for abrasive, which allows all abrasive leave the turbine when they reach the highest speed with the least internal bounce and self-wear. Can offer high blast speed and full abrasive cover.

The maximum thickness of blast wheel shell can reach 70mm, better sealing effect, long service time.

The interior of the blasting wheel is turbo type, abrasive will not not stay in the distributor. Abrasive utilization rate increased to 99%, improve efficiency by 30%.

Blast wheel bottom has cushioning rubber, which can reduce vibration.

The material of impeller is 40CrMnMo, the material of blade is high chorme wear-resistant casting iron, the hradness can reach HRC60-65.

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro