Maintenance and care of shot blasting machines

Shot blasting machine in the use of the same time, but also experiencing wear and tear, routine maintenance and maintenance of shot blasting machine life extension, to maintain the efficiency of the work plays a key role, maintenance and maintenance of shot blasting machine on the safety also has a very important significance, timely safety hazards and solve. The following is the daily maintenance, weekly maintenance, monthly maintenance, and quarterly maintenance methods of the shot blasting machine.

Daily maintenance and care

1. All shot blasting machines and shot blasting machine motor on the fixed bolt has no loose, found loose immediately tighten.

2. Shot blasting machine wear parts and shot blasting indoor guard wear, and timely replacement of worn shot blaster parts.

3. Check the blade, wear half of the time must be replaced.

4. Check the directional sleeve pointer position is correct.

5. The shot blasting machine maintenance door is closed tight.

6. Dust removal pipeline has no air leakage, dust removal filter bag in the dust collector has no dust or broken.

7. Separator spiral shell and filter sieve on the accumulation of debris and other debris and timely removal.

8. Check whether the flow curtain of the separator is uniform and forms a full curtain.

9. Check whether the electronically controlled pill supply gate valve is closed.

10. Check whether the status of each limit switch and proximity switch is normal.

11. Check whether the working status of the signal indicators on the control table is normal.

12. check whether the current of the shot blasting motor is within the rated range.

13. Clean the dust on the electrical control box.

14. Check the wear and tear of the inlet pipe gasket, the rubber guard of the working door and the top seal to avoid the loss of projectiles.

15. Clear the debris from the bottom plate grille to ensure the recovery of the pellets.

16. Check whether the total amount of pellet material in the abrasive silo is sufficient, insufficient should be added.

Weekly maintenance and servicing

1. Check the distributor, if it is worn by more than 3mm, it should be replaced.

2. Check the control cage, the opening increases by 6mm or more should be replaced.

3. Check whether the industrial shot blasting equipment guard plate is seriously worn and misaligned.

4. Check the shot blasting machine triangle belt tensioning, should be able to press in about 10mm, otherwise should be adjusted.

5. Check the wear and tear of the partition and skid plate, if necessary, should be replaced in a timely manner.

6. Check whether there are qualified projectiles in the fine powder tube and the large block tube that can be recycled.

7. Check whether the belt tensioning, bolts and joints of the bucket elevator are suitable and whether they are run off and worn.

8. Check whether there are foreign objects and wear in the screw conveyor.

9. Check the bottom plate grating, if there are any loopholes, repair them in time.

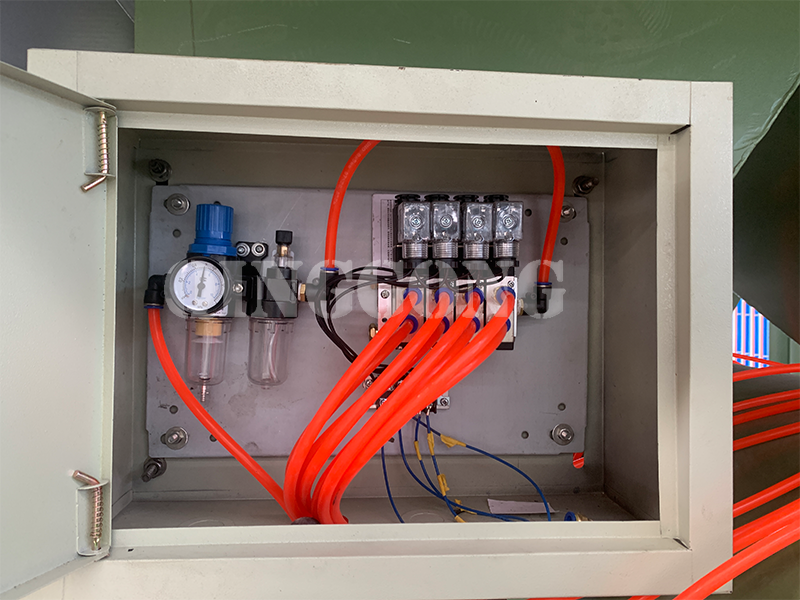

10. Check the sleeve joints to avoid leakage of air, dust, etc.

11. Check the dust on the dust collector cartridge and use the pulse back-blowing mechanism in time.

12. Lubricate the bearing seats of the four blast machines once.

Monthly maintenance and servicing

1. Check and adjust the gate valve so that its opening and closing degree meets the current value of 25A to 30A of the shot blast machine motor.

2. Adjust the tightness of the drive chain, and give lubrication.

3. Check the belt tightness of the bucket elevator and adjust it; check the hopper bolts and tighten them.

4. Check the lubricating oil of the reducer, if it is lower than the specified oil level, it should be filled with corresponding grease.

5. Check the contact status of each AC contactor and knife switch, and carry out dust blowing and cleaning.

6. Check whether the power and control part of the wire and cable is loose, and should be tightened.

7. Single test for each motor separately, listen to the sound is normal, see the size of no-load current, no less than 5 minutes for each motor.

8. Check the fan, air duct wear and fixation.

9. Fill the bearing seat of the two heads of the hoist, separator and screw conveyor with 2# calcium-based grease once a month.

10. Change the oil of the air compressor once a month.

Quarterly maintenance and servicing

1. Check the integrity of the bearings and electric control box, and add grease.

2. Check the wear and tear of the blast machine wear shield.

3. Replace the bearings of the main shaft of the blast machine and the bearings of the blast motor with new high-speed grease.

4. Check the tightness of the fixed bolts and flange connections of all motors, reducers, fans and screw conveyors.

Annual maintenance and servicing

1. Overhaul the lubrication of all bearings (including motor bearings) and replenish with new grease.

2. Replace or weld the main chamber body shield.

3. Check the contact reliability of PLC and inverter.

4. Check the ammeter for accurate display.

5. Check the dust collector cartridge, if it is damaged it needs to be replaced, if there is too much sticky ash then clean it with an air gun.

6. Make necessary unblocking and repair of the air ducts.

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro