Rotary Table shot blasters are for Items that do not lend themselves to being tumbled (tumble belt) or hung (hanger spinner). Suitable for blasting of numerous small parts (with sufficient density to resist the energy created by the abrasive) up to items which are large but will fit within the work envelope.

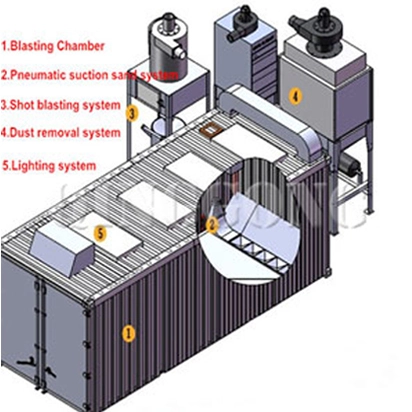

During the shot blasting process, the table rotates passing the workpieces through the blast stream from one or more blast turbines.

Qinggong machinery has successfully installed a rotary table shot blasting machine for Egypt customer on September 17th. The customer used this machine to clean the Weld assembly.

This type of machine is our hot selling in the foreign market. With two blasting turbines, the power of each turbine is 7.5 KW. The effective cleaning of maximum size is Φ1200. The cleaning time is 5-8 mins and needs to flip over to ensure full cleaning effect.

The machine can have the table fitted to the machine's door, which enables loading with a hoist or fork-lift truck to the entire surface of the table.

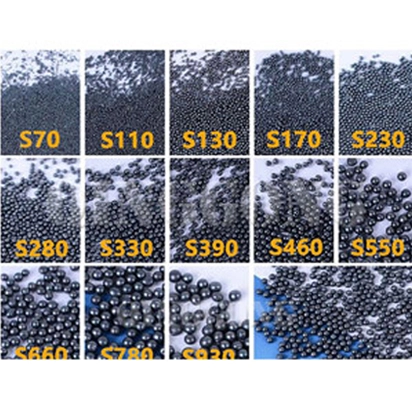

The blast chamber used a ZGMn13 steel guard, which is hard enough to deal with the shot blasting from 35HRC to more than 55HRC. The high strength abrasion-resistant natural rubber sheet, to protect the turntable and rotating motor.

The rotating motor drives the platform to rotate, let the abrasive completely cover the workpiece.

Design the maximum door size to ensure that the workpiece can get in and out of the equipment smoothly.

3-layer rubber seals for the gaps around the door, ensure the abrasive will not out the chamber.

With 100+ workers, 22 engineers, and a service team of 10, QGMA have the capability to meet your requests of shot blasting and sand blasting machines. Welcome to contact us.

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro