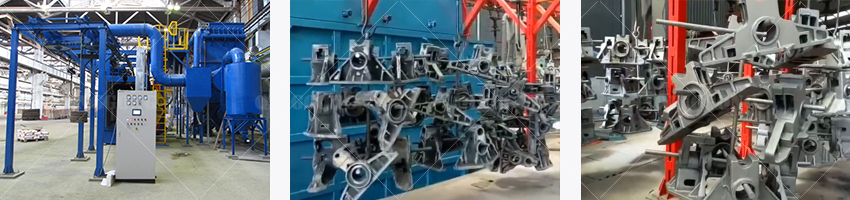

Overhead rail shot blasting machine allows the workpieces to move with constant speed through the machine. The conveyor consists of a chain and trolley system suspended from a monorail, and can be driven at a constant speed or can be indexed.

A special feature of the continuous shot blasting machine is the constant traveling speed of the workpieces. The ability to adapt the moving speed of the workpiece and the wheel power ensures that the machine can be easily and smoothly integrated into an existing production line. The abrasive is pre-accelerated very efficiently by the KT series blast wheels, allowing for short treatment times and reduced abrasive consumption when compared to conventional blast wheels. Maximum coverage of the workpiece is achieved by the blast wheels being arranged in an "X" alignment, diagonally to the moving workpiece. In this formation, the leading edges of complex components, welded sections, and flame-cut parts can be thoroughly blasted.

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro