In today's rapidly evolving industrial landscape, staying at the forefront of technological advancements is crucial. One such innovation that has revolutionized the manufacturing industry is the conveyor shot blasting machine. This powerful equipment allows for efficient and effective surface preparation of various materials, enhancing productivity and product quality. In this blog, we will explore some of the recent advancements in conveyor shot blasting machine technology that have garnered significant attention and praise.

Enhanced Efficiency and Throughput

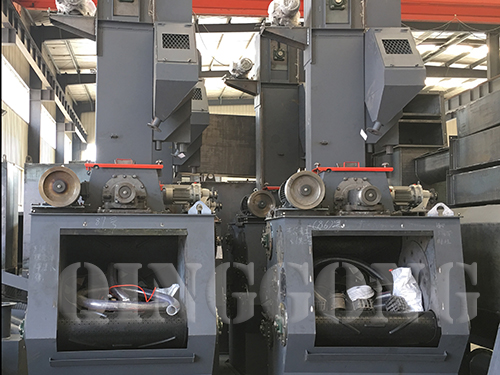

The latest conveyor shot blasting machines have witnessed remarkable improvements in efficiency and throughput. Manufacturers have utilized advanced control systems and integrated robotics to streamline the entire process. The incorporation of smart algorithms has allowed for optimal blast wheel positioning, resulting in more consistent and uniform surface cleaning. Additionally, the integration of conveyor speed control mechanisms enables manufacturers to adjust the machine's pace according to specific requirements, further enhancing efficiency.

Advanced Shot Blasting Techniques

To cater to a wide range of applications, conveyor shot blasting machines now offer advanced shot blasting techniques. From the traditional wheel blasting to airless centrifugal blasting and air-blast peening, manufacturers have introduced various methods to meet diverse surface preparation needs. These techniques not only ensure the removal of rust, scale, and other contaminants but also enable controlled surface profiling for enhanced coating adhesion.

Intelligent Control Systems

The advent of Industry 4.0 has paved the way for intelligent control systems in conveyor shot blasting machines. These systems leverage data analytics and machine learning algorithms to optimize the entire process. Real-time monitoring of operating parameters, such as blast pressure, abrasive flow, and conveyor speed, enables manufacturers to proactively address any deviations and fine-tune the process for optimal performance. This advanced level of automation not only improves productivity but also minimizes downtime and enhances worker safety.

Eco-friendly Solutions

As sustainability becomes a key focus for industries worldwide, conveyor shot blasting machine manufacturers are also aligning their technology with eco-friendly practices. Innovations such as closed-loop abrasive recovery systems and dust collection units have significantly reduced abrasive consumption and enhanced air quality in the working environment. These eco-friendly advancements not only contribute to a greener future but also help businesses reduce operating costs associated with material waste and environmental compliance.

In conclusion, advancements in conveyor shot blasting machine technology have propelled the manufacturing industry to new heights. From enhanced efficiency and intelligent control systems to advanced shot blasting techniques and eco-friendly solutions, these innovations have revolutionized surface preparation processes. As the demand for higher productivity and product quality continues to rise, it is pivotal for businesses to stay informed and leverage these technological advancements for a competitive edge. Embracing conveyor shot blasting machines is not only an investment in efficiency but also a commitment to innovation and sustainability. So, whether it's removing rust or preparing surfaces for coatings, a conveyor shot blasting machine should be a top consideration for any business aiming to stay ahead in the fast-paced manufacturing world.

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro