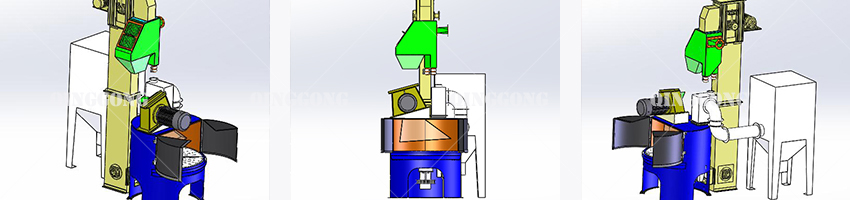

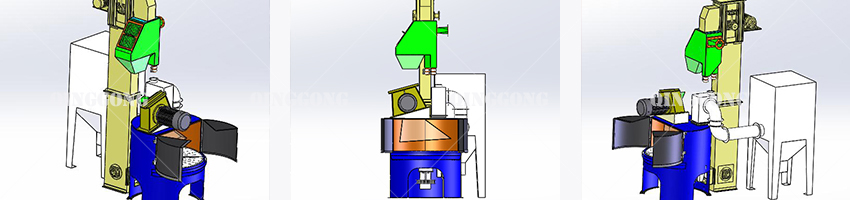

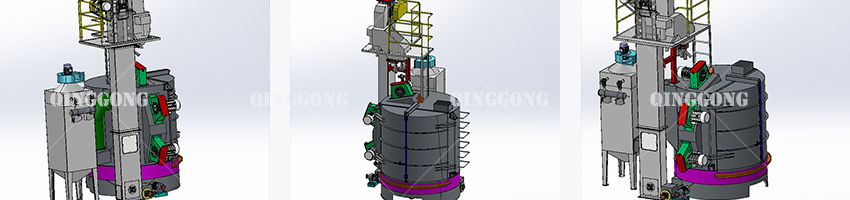

Rotary Table Shot Blasting Machines Basic Specification

| ITEM | RT1000/900 | RT1200/900 | RT2000/1500 |

| Maximum dimension of chamber (mm) | Φ1350×560 | Φ1350×860 | Φ2654×560 |

| Maximum workpiece weight (kg) | 400 | 400 | 1000 |

| Diameter of Turn Table(mm) | Φ1200 | Φ1200 | Φ2500 |

| Number of blast wheels and power (kw) | 11 | 2×7.5 | 2×15 |

| Overall dimension (mm) | 1500×3450×3780 | 1900×3450×4160 | 4260×3647×5366 |

| Material of table | Manganese | Manganese | Manganese |

| Ventilation requirements (m3/h) | 4000 | 6000 | 8000 |

| Material of Protective lining | Manganese/Cast alloy | Manganese/Cast alloy | Manganese/Cast alloy |

| Material of blast chamber | Mild steel | Mild steel | Mild steel |

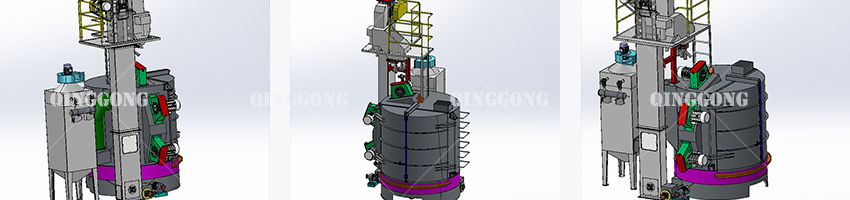

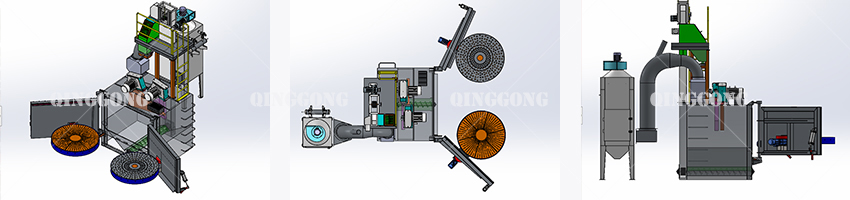

Swing Tables Shot Blasting Machines Basic Specification

ITEM | RTD1000 | RTD1200 | RTD2000 |

Maximum Diameter of Rotary table (mm) | Φ1000 | Φ1200 | Φ1500 |

Maximum workpiece weight (kg) | 400 | 400 | 1000 |

Number of blast wheels and power (kW) | 11 | 2×7.5 | 3×11 |

Material of table | Manganese | Manganese | Manganese |

Ventilation requirements (m3/h) | 4000 | 6000 | 8000 |

Material of Protective lining | Manganese/Cast alloy | Manganese/Cast alloy | Manganese/Cast alloy |

Material of blast chamber | Mild steel | Mild steel | Mild steel |

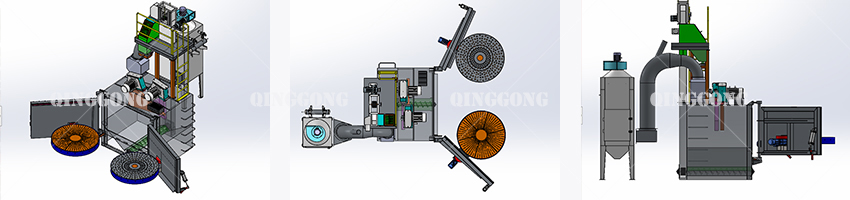

Rotary Table Shot Blast Machinery Systems

Treated objects are loaded on a perforated rotating table. A big door, provide simple and fast loading. This shot blasting for sale can have the table fitted to the machine's door, which enables loading with a hoist or fork-lift truck to the entire surface of the table. The double table blasting machine also can be equipped with two tables, enabling simultaneous shot blasting of treated objects inside the machine and loading or turning treated objects in front of the rotating table blasting machine.

The rotatory shot blasting machine's housing is robust and protected by wear-resistant materials. High efficiency of the machine is enabled by the system for continued returning and cleaning of the abrasive, along with efficient turbines made from wear-resistant materials. Standard equipment of larger rotary shot blast machine includes PLC Siemens, display, timer automatic or manual mode, automatic start-up of turbines, working-hours counter, etc. For shot blasting cast containing larger quantities of casting sand, a magnetic sand cleaner may be installed.

Key Benefits and Features of Rotating Table Blasting Machine

Customized, meet workpiece and workshop requirements.

Easy to install and operate.

Factory outlet, bottom price

Wide application, one machine with multiple workpieces.

High quality, 3 times acceptance

Acceptance three times before delivery

Equipped with environmental protection equipment, fully meet local environmental requirements

Applications of Rotating Table Blasting Machine

Descaling for forgings and castings

Descaling for metal piece

Deburring for die cast parts

Descaling for heavy workpiece

Advantages of Rotary Shot Blast Machine

1. Compact structure, small volume.

Due to the rotary motion, the equipment has a large effective volume; at the same time, by adjusting the rotational speed can change the size of the effective volume of the chamber, so the rotary table type shot blasting machine has the advantage of compact structure.

2. Easy to use.

Simple and reliable operation, and according to the size of the workpiece can be adjusted to different conveying speed and conveying volume. In addition, according to the need to choose different forms of nozzles and arrangements to achieve the cleaning requirements of different workpieces.

3. Better sealing.

Because of its transmission device for the gear reducer driven vane pump to realize the supply and discharge of material work cycle process, so in the operation process will not be due to dust pollution of the environment.

A Video of Rotary Shot Blast Machine

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro