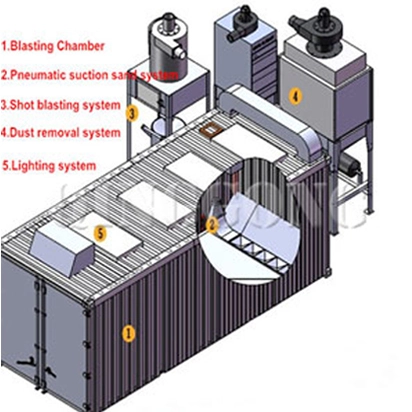

For the blasting system, you can choose the air blast or wheel blast by manual or automatically blast cleaning.

The automatic blast machine have high productivity and energy saving advantages, it is your first choice for the preparation line.

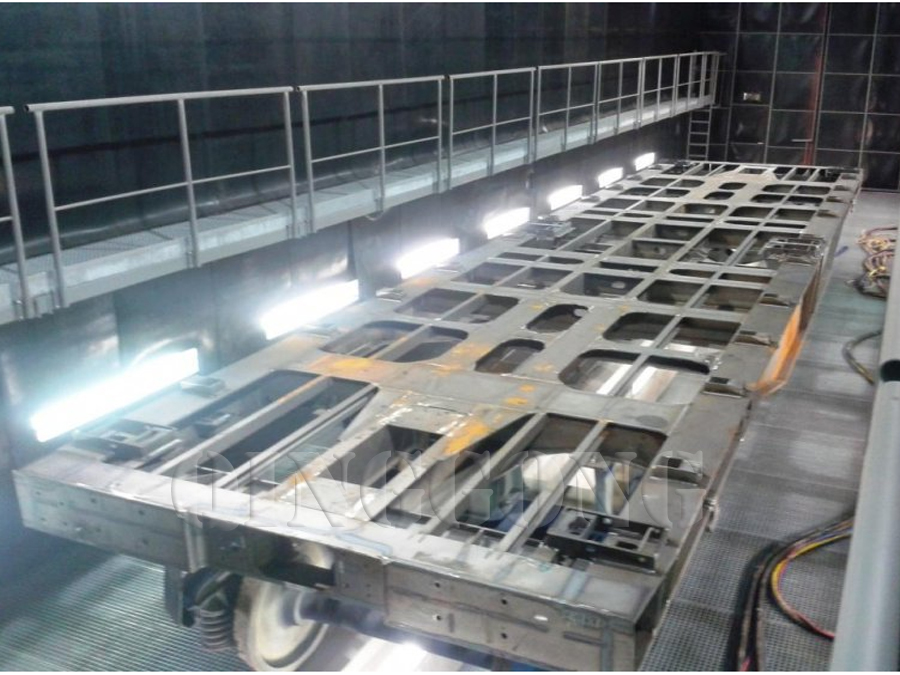

But sometimes due to the blast cleaning object items special structure or productivity requirements, the customer prefer to choose the tailored blast room system.

The underfloor recovery systems

Underfloor recovery systems are installed to recover spent abrasive, convey it to the abrasive separation system and onto storage ready for reuse without any manual labour being required in the case of full recovery, or minimum labour in the case of partial recovery floors.

There are two main types of Recovery Systems used.

These are:

1.Pneumatic "Waffle" type floors

2.Mechanical Sweeper floors

Pneumatic "Waffle" type floors

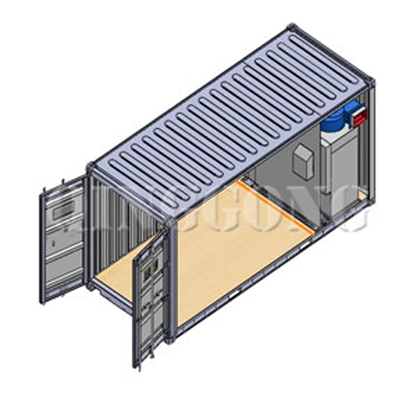

Qinggong's waffle floor system is a modular pneumatic vacuum recovery solution that can be fitted to any blast room project.

High velocity air is drawn through the center duct and down the length of the waffle module; spent abrasives and debris falling into individual hoppers are pneumatically conveyed down the center duct to the adjustable cyclonic reclaimer assembly.

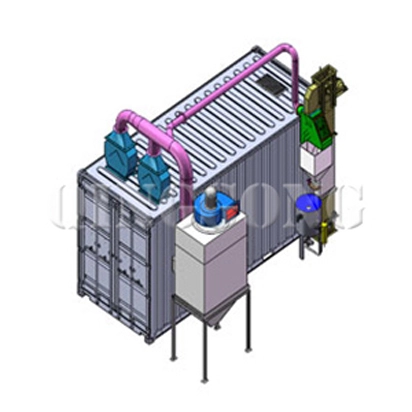

Mechanical scraper abrasive recovery system

The most specified product in our range. This scraper floor has many features that separate it from those offered by our competitors. The scrapers comprise of a natural rubber flap set against a steel comb, multiples of which are set inlong frames.

The depth of the recovery channel is only 200mm to 500mm ensuring that in many instances, ie. Those where objects being taken into the booth may be carried by hand, it can be located directly onto an existing factory floor. When a flush finish is required between the factory floor and the blast room, only minor excavation is required. The scraper system is covered by a pedestrian grating on which the operator stands and through which the abrasive falls. In certain applications when heavy items are being processed, this grating can be increased in strength to provide greater loading capacities. An alternative method of supporting a heavier item is to incorporate rails into the floor, positioned conveniently between the recovery corridors on which a bogie can be mounted.

It is very convenient to maintenance the scraper.

Perhaps the first question that needs to be asked is what criteria will help me to decide which is best for my application? What disadvantages and advantages does each have?

Please do not heistate to contact us immediately, our professional sales will help you to get contact with our professional engineer.

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro