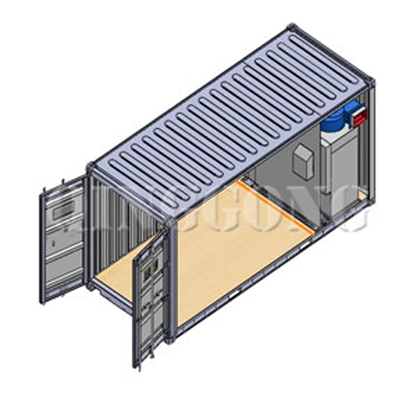

Last month, Qinggong Machinery has delivered a set of overhead rail shot blasting machine to the customer’s workshop, and acceptance was successful. The customer mainly used to clean the desks and chairs parts. The productivity capacity need to be large, so our engineering team designs the three working stations. It can work in batch within one time and satisfied with customer’s requirements.

The overhead rail shot blasting machine is the step by step type machine with three working station. When one batch of the workpiece move into the blasting chamber, the pneumatic gate close and the workpiece for rotation. Each workpiece are hit by the dense steel shot with the high spray speed from two different coordinate. The workpiece working time about 5-6 minutes, and the rotation device are move front and back with the workpiece. After finished the shot blasting, the pneumatic gate open and the hanging conveyor bring the workpiece move out the blasting chamber. The steel shot and dust mixture in the shot blasting progress will falling down in the bottom screw conveyor, and then transport to the bottom of the bucket elevator. Then the elevator hopper bring the mixture into the separator, then after separate the cleaned steel shot will fall into the storage hopper to recycle to use. The dust produced in the shot blasting progress will via duct to the dust collector system. The clean air after purification is discharged into the atmosphere, and the particulate dust is captured and collected.

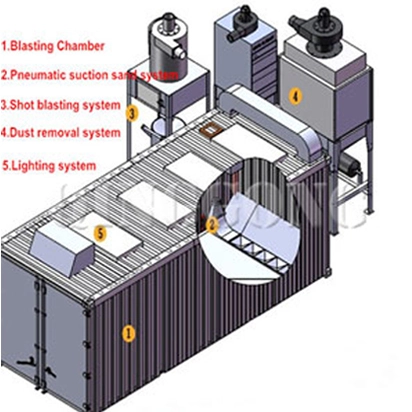

The overhead rail shot blasting machine is composed with blasting chamber, screw conveyor, pneumatic gate, hanging conveyor, rotation device, abrasive apply system, bucket elevator, separator, dust collector, blast turbines, unloading system, pneumatic system, electrical system and other components.

1. Blasting chamber

The blasting chamber adopt to the box welded steel construction and let the shot blasting working in the inner room. On the inlet and outlet chamber have three-layer seal rubber curtain, a set of pneumatic gate and on the side of the blasting chamber have six units blasting turbines on the different coordinate, which will clean the workpiece surface evenly. The blasting chamber wall should bear the impact of the steel shot stream. The inner wall is lined with a wear-resistant protective plate and bolted with a cast nut to protect the head of the bolt from damage. It is easy to disassemble and replace. There is a revolving closed channel at the top of the chamber to facilitate the unblocking of the hook and prevent the spillage of dust and steel shot.

2. Hanging conveyor system

The hanging conveyor chain of the shot blasting machine is a detachable chain, which allows the hook to run continuously along the revolving track. It is composed of rails, brackets, slewing devices, large and small sprocket sets, tensioning devices, driving devices and other components

(1). Tensioning device

The shot blasting machine tensioning device is used to compensate for chain length and chain length manufacturing errors, which is beneficial to the installation of the chain and compensates for the influence of the increase in the chain pitch due to wear during operation, so as to maintain the tension of the chain and eliminate the possibility of the line the resulting tension.

(2). Drive device

The driving device of the shot blasting machine adopts ×-100-16-5 reducer to drive the chain to run, and the chain runs at a stable speed.

3. Rotation device

The rotation device of the shot blasting machine consists of a double-stage cycloid pinwheel reducer XLED1.5-63-1/385 and a sprocket to drive the transmission chain to mesh with the sprocket on the hook. The workpiece can be moved in a straight line or in a rotary motion, so that the workpiece can be shot blasted from various angles. Properly adjust the tension to maintain the tightness of the transmission chain. The cleaning speed is adjustable.

4. Bucket elevator

(1). The flat belt drive bucket elevator of this machine lifts the steel shot and dust mixtures from the lower funnel of the cleaning room to the separator on the upper part of the machine.

(2). The upper and lower belt pulleys with the same diameter of the hoist are selected from spokes, steel plates and hubs to form a polygonal structure. Effectively increase the friction force, make the lifting belt run reliably and smoothly, avoid slipping, and prolong the service life of the belt.

(3). Open the cover of the middle shell of the bucket elevator to repair and replace the hopper and the overlap belt.

(4). Open the cover on the lower shell of the bucket elevator to eliminate the blockage of the bottom projectile.

(5). Adjusting bolts on both sides of the upper shell can adjust the tightness of the transmission belt.

5. Separator

The overhead rail shot blasting machine adopts foreign comprehensive technology and designed and made full curtain separator, which can effectively separate qualified projectiles, sand, oxide scale and dust. The separation efficiency of more than 99%. The high separation efficiency not only effectively prolongs the service life of vulnerable parts such as blades, but also improves the cleaning effect.

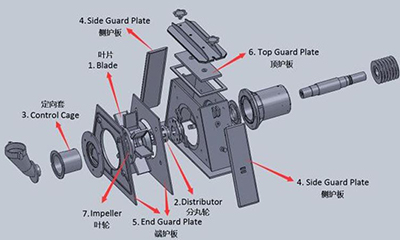

6. Blasting turbine

This shot blasting machine adopts six sets of KT series blasting turbines, which has large ejection volume, high ejection speed and good cleaning effect. The shot blasting machine is composed of an impeller, a main shaft and a bearing, a casing and the guard plate, distributor, control cage, a set of blades, an internal and external linkage disk, and an pill tube. The steel shot enters the pill tube and flows into the blasting turbines. After pre-acceleration, it is thrown out through the window of the control cage, and the blades are accelerated and thrown toward the workpiece to achieve the purpose of cleaning.

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro