Features of Servo CNC Turret Punching Machine

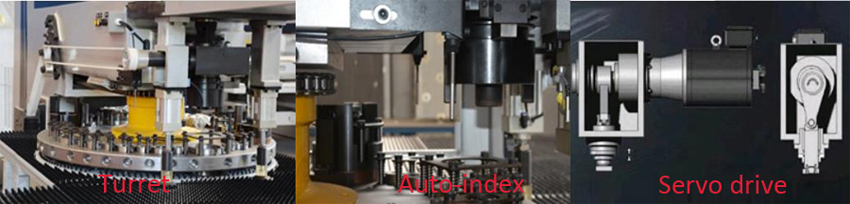

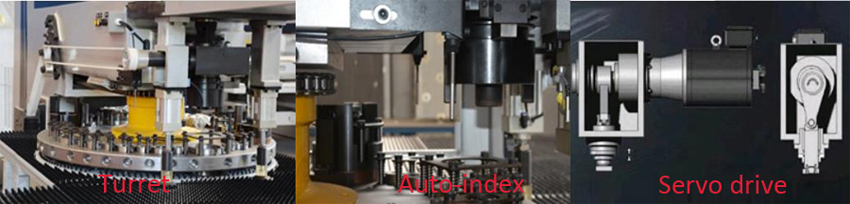

Servo drive

Direct driving structure

Sealed oil tank, prefect lubricating with lower temperature rising.

Turret

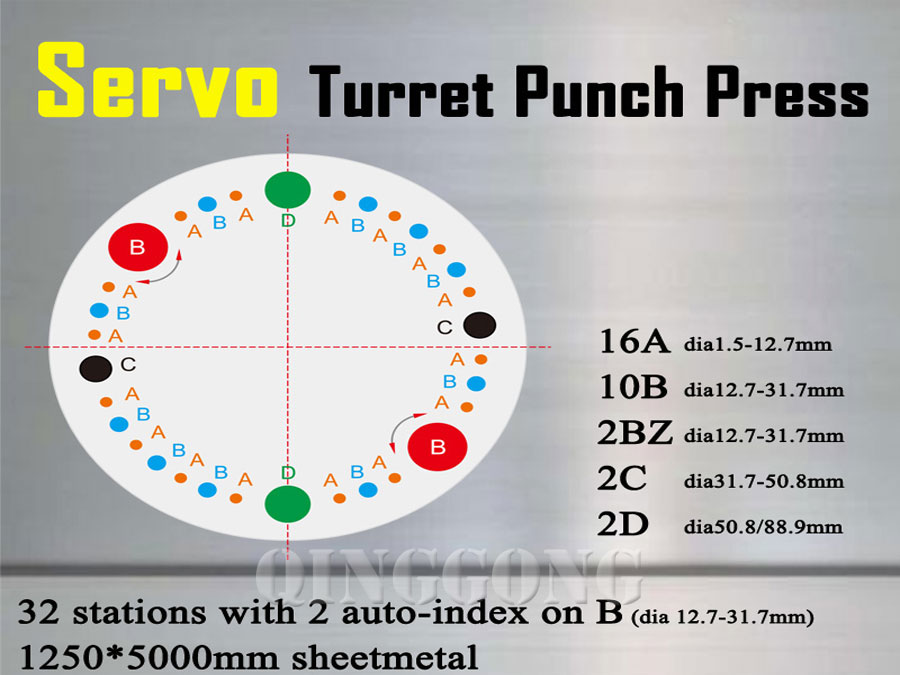

32 working stations

Material: 40Cr

Pair machining in large scale machine center.

Adopt Amada standard long tools.

Super high accuracy position pin ensures the aligment of punch and die

Auto-index

Worm and gear driving structure ensures the accuracy of double direction.

Singal synchronous driving belt ensures the accuracy of punch and die.

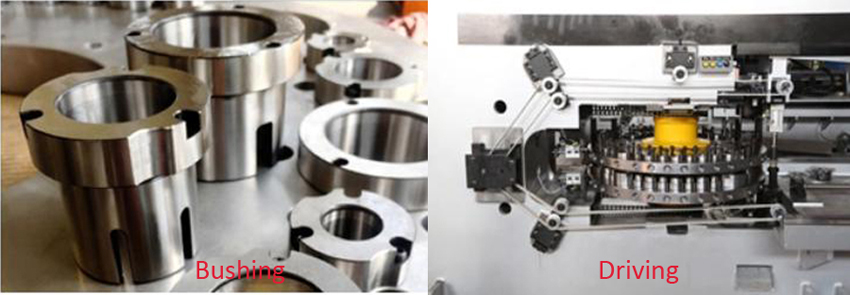

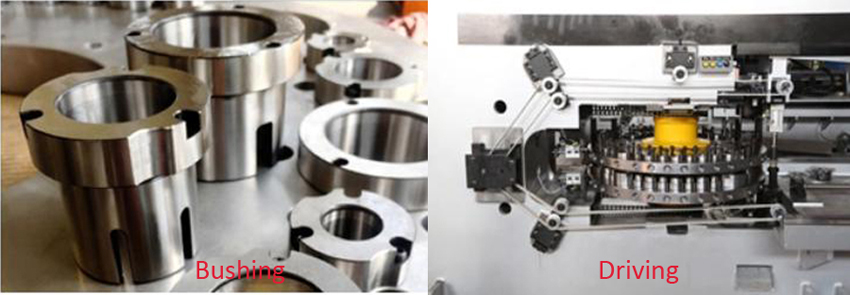

Bushing

Each station has high accurate bushing.

40Cr material

International standard long toolings

Driving

T axis is driving by one servo motor with chains

C axis is driving by one servo motor with a belt.

Basic Specification of Servo CNC Turret Punching Machine

Serial | Name | unit | Parameters |

1 | Model | / | S30-A | S30-B |

2 | Workstation | number | 26 | 32 |

3 | Punching pressure | KN(T) | 200(20) |

4 | Punching form | / | servo drive |

5 | Frame structure | / | Closed bed |

6 | machined sheet metal | X | mm | 5000(Relocating with one time) |

Y | mm | 1250 or 1500 |

7 | thickness of machined sheet metal | mm | <6 |

8 | stamping frequency | cpm | <1500 |

9 | Pliers number | only | 3 |

10 | Clamp mechanism | / | Pneumatic |

11 | Repositioning cylinder | set | 2 |

12 | Rotating station | / | 2 |

13 | Control axis number | / | 5(X、Y、W、C、A) |

14 | Turntable diameter | mm | 1040 |

15 | Mould form | / | Thick turret and long die |

16 | Worktable structure | / | Brush plate and floating universal ball |

17 | Punching accuracy of primary positioning | mm | ±0.1 |

18 | maximum carrying weight | Kg | <150 |

19 | Gas source | Mpa | 0.5 |

20 | Total power | KW | 30 |

21 | speed of sheet movement | m/min | <70 |

22 | Rotating tower speed | r/min | 30 |

23 | Machine weight | ton | 12 |

24 | Outer size | mm | 4600*5100*2000 |

Mold distribution

| A ~12.7mm | B ~31.7mm | C ~50.8mm | D ~88.9mm |

26 turret (including 2 B stations rotating) | 10 | 12 | 2 | 2 |

32 turret (including 2 B stations rotating) | 16 | 12 | 2 | 2 |

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro