Qinggong machinery as a most professional shot blasting machine manufacturer. We always have strict request on industrial shotblaster product quality.

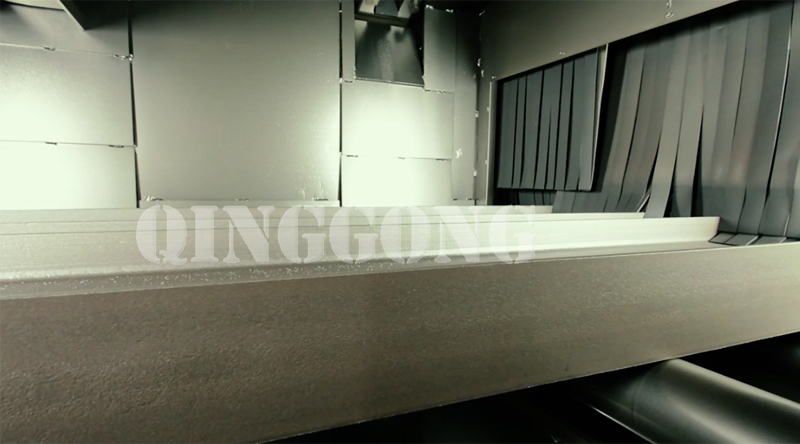

The shot blasting machine indoor guard have 65Mn, wear-resistant cast iron, ZGMn13, rolled Mn13 and other material. Among them, the rolled Mn13 is the best wear-resistant material. Qinggong machinery is adopt to Mn13 material for blasting chamber and can maintenance free for 10 years under normal operation.

The features of Mn13:

1. Mn13 is a high-manganese wear-resistant steel, which is the best choice for wear-resistant materials such as strong impact and high-pressure material wear. The characteristics of high manganese steel is: one is the bigger external impact the higher wear resistance of the surface layer; the other one is that with the gradual wear of the surface hardened layer the new layer will be form.

2. Mn13 steel plate has excellent wear resistance, strong impact wear and large stress wear. It easy to machining, cutting, welding and bending.

3. Mn13 steel plate can effectively reduce the cost of machine wearing shot blaster parts, save maintenance cost and improve the competitiveness.

The surface of the steel plate is processed under the action of large impact load or large contact stress. The surface hardness is rapidly increased from HB200 to above HB500 and inform s highly wear-resistant surface layer. The inner Austenite of the steel plate still maintains good impact toughness. So it has the work hardening characteristics unmatched by other wear-resistant materials.

Qinggong machinery aims to make customer satisfied with the machine such as steel shot blasting equipment and bring profits to customer. Please no hesitate to contact us if you have any interested in shot blasting machine.

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro