In industries that rely heavily on surface preparation and cleaning, such as manufacturing, construction, and foundries, efficient and cost-effective methods of achieving desired results are paramount. One such method that has gained significant popularity is the utilization of steel shot machines. In this blog, we will delve into the cost analysis and return on investment (ROI) associated with using these machines, highlighting the numerous benefits they offer and the financial gains they can bring to businesses.

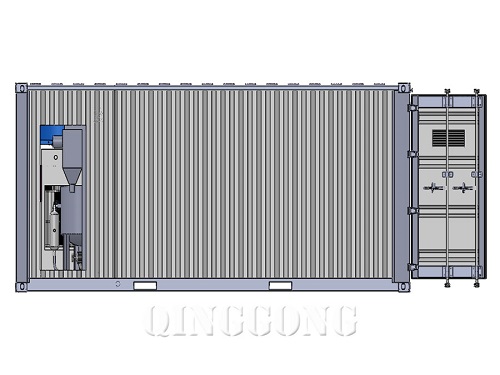

Understanding the Steel Shot Machine

Before diving into the cost analysis, it is essential to grasp the concept of steel shot machines. These machines are powerful and versatile tools used to clean, descale, and prepare surfaces by propelling small steel shots at high velocities. The abrasive nature of the steel shots aids in removing contaminants, scale, paint, and other impurities, leaving behind a smooth and clean surface.

Factors Influencing the ROI of Steel Shot Machines

Efficiency and Productivity

One of the primary factors that contribute to the ROI of steel shot machines is their remarkable efficiency and productivity. These machines are capable of quick and consistent surface preparation, significantly reducing labor hours required for traditional methods. The increased productivity leads to higher throughput, allowing businesses to take on more projects and generate additional revenue.

Cost Savings

When compared to traditional surface preparation methods, steel shot machines offer substantial cost savings in the long run. By reducing or eliminating the need for chemicals, solvents, and manual labor, businesses can save on material and labor costs. Additionally, fewer consumables and reduced waste disposal expenses further reinforce the economic advantages of utilizing these machines.

Calculating the ROI of Steel Shot Machines

Initial Investment

To determine the ROI of steel shot machines, businesses must consider the initial investment required. This includes the purchase or lease price of the machine, any necessary accessories, and the cost of training personnel. While the upfront investment may seem significant, it is vital to consider the long-term financial benefits.

Operational Costs

Analyzing the operational costs is crucial to accurately assess the ROI. This includes expenses associated with power consumption, maintenance, and occasional replacement of worn-out parts. However, the low maintenance and durability of steel shot machines contribute to lower ongoing costs, ultimately benefiting the ROI.

Reduction in Labor Costs

One of the most impactful factors influencing ROI is the reduction in labor costs. By minimizing manual labor-intensive surface preparation methods, businesses can allocate their workforce to more productive tasks, enhancing overall operational efficiency and reducing labor expenses.

The utilization of steel shot machines offers significant advantages in terms of cost savings, increased productivity, and enhanced workplace safety. By analyzing the initial investment, operational costs, and reduction in labor expenses, businesses can effectively measure the ROI of incorporating these machines into their surface preparation processes. The tangible and intangible benefits ensure long-term financial gains along with improved quality and durability. To maximize their ROI, businesses should consider investing in reliable steel shot machines, making them an invaluable asset in enhancing productivity and profitability.

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro