Key Features of Wire Mesh Belt Shot Blasting Machines

Wire mesh belt shot blasting machines provide uniform cleaning while protecting fragile or thin workpieces from deformation. The steel mesh belt shot blasting machine uses adjustable blasting speed and intensity, enabling manufacturers to achieve the exact surface roughness needed for painting, coating, or bonding.

Customized Belt Conveyor Blast Machine Solutions

Every production line has unique requirements. A belt conveyor blast machine can be customized to match different workpiece sizes, production speeds, and cleaning intensities. For heavy-duty industries, the manganese steel belt shot blasting machine offers enhanced wear resistance and long service life.

Applications of Continuous Horizontal Conveyor Belt Shot Blasting Machines

These continuous horizontal conveyor belt shot blasting machines are widely used in automotive, aerospace, hardware, and foundry industries. From rust removal to surface finishing, a customized mesh belt shot blasting machine ensures efficiency, consistency, and cost savings for large-scale industrial applications.

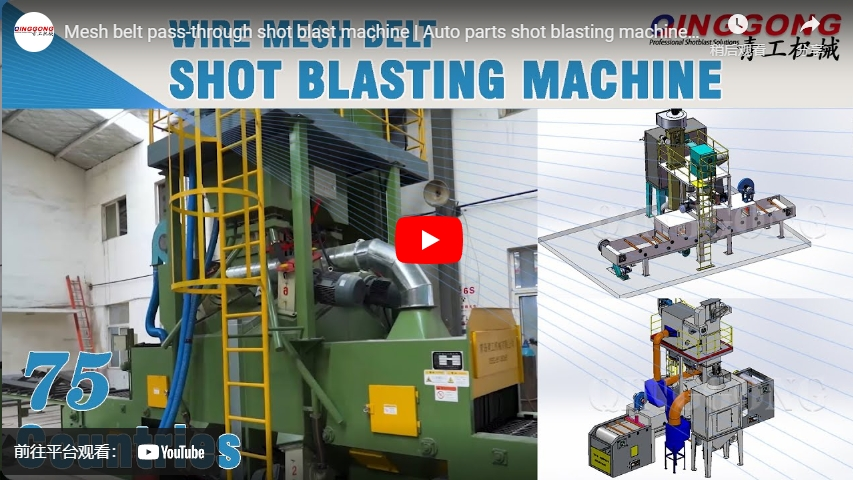

A Video of Belt Conveyor Shot Blasting Machine

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro