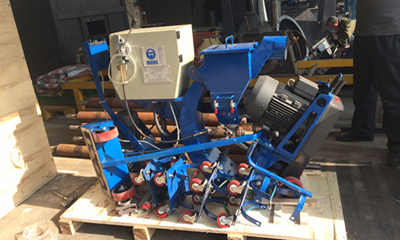

Recently QINGONG Machinery has successfully delivery an overhead rail shot blasting machine for our domestic customer. Let me give a brief introduction of this machine.

The overhead rail shot blasting machine is suitable for shot blasting of small cast iron parts, steel castings, forgings and stampings. It is especially suitable for the cleaning of forgings and castings to remove the sand, rust, scale and dirt on the surface of the workpiece. Etc., the surface of the workpiece is rendered metallic, the internal stress of the workpiece is eliminated, the fatigue resistance of the workpiece is improved, the adhesion of the paint film during the painting of the workpiece is increased, and the surface and the intrinsic quality of the workpiece are finally improved.

The customer needs to use the shot blasting machine to blast clean the steel castings in batch.

However, the customer's workshop space is limited, and the layout space reserved for the shot blasting machine is small, and it is difficult to use large machines to improve the cleaning efficiency. Based on our engineers' years of design experience, combined with the working principle of the industrial shot blaster, and finally adopting the design method of the foreign integrated shot blasting machine, let me introduce the advantages of the integrated shot blasting machine.

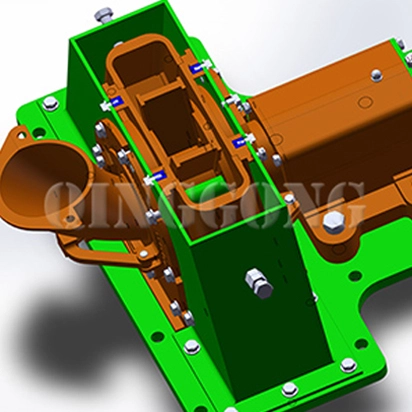

Combining the dust collector with the front and rear sealed chambers of the shot blasting machine, the dust collector does not require additional installation space, which greatly reduces the space occupied by the equipment layout.

Install a dust collector on the inlet and outlet sealed sides to ensure the required air volume when the shot blasting machine works, thereby ensuring the dust removal effect of the dust collector.

Reduce the production cost and transportation cost of the equipment.

The connecting air pipe between the traditional dust collector and the shot blasting machine is reduced, and the user is more convenient in installation, use, repair and maintenance.

Provides new ideas for users to solve the problem of insufficient installation space.

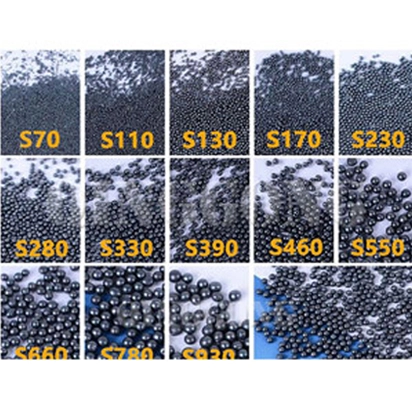

This overhead shot blasting machine uses four high-efficiency blasting turbines, which are arranged according to the ejection coordinates to shorten the cleaning time and improve the cleaning quality. When the workpiece is continuously moved to the indoor abrasive projecting area, all sides of the body are continuously and uniformly projected and cleaned in different directions. The separator adopts a full curtain separator, which has a good separation effect. The separation efficiency of shot, slag, and dust is up to 99%. The shot blasting room is equipped with a spacious maintenance door, which is beneficial to increase the indoor dust removal effect, protects from the high temperature of the shot blasting machine for a long time, and reduces the wear of the indoor hanger and its protective plate. , The blasting turbine of the catenary shot blasting machine is easy to repair and replace the wearing parts, has good wear resistance and long service life. Clean the indoor guard plate with wear-resistant nuts to cover and bolt to protect the bolt head from damage, easy disassembly and replacement, long service life of the guard plate and nut, and small maintenance.

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro