Industrial shot blasting machine, an outstanding representative of casting or forging process, has such a wide range of applications, like stars adorning the vast sky of industrial production. With its unique shot blasting technology, it has brought revolutionary changes to many industries.

Uses of industrial shot blasting machines

Cleaning surface dirt and oxide layers

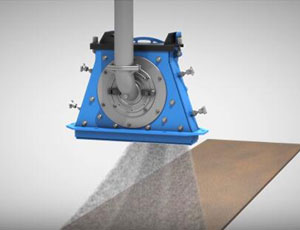

During the manufacturing process, the surface of workpieces often gets contaminated with dirt, oil stains, dust, and other impurities, which cannot be removed through simple cleaning. An industrial shot blasting machine can thoroughly clean the surface dirt and oxide layers, providing a good foundation for subsequent surface preparation treatment.

Improving surface smoothness and roughness

An industrial shot blasting machine can polish the surface of workpieces, increasing their smoothness and achieving a mirror effect. At the same time, the roughness of the workpiece surface can be controlled by adjusting the granularity of the shot blasting material to meet different requirements.

Enhancing surface hardness and wear resistance

Shot blasting treatment can change the physical and chemical properties of the workpiece surface, such as increasing surface hardness, wear resistance, and corrosion resistance. These techniques are vital for manufacturing high-strength, high-wear-resistance, and high-corrosion-resistance parts.

Improving coating adhesion

Before surface coating, the workpiece surface needs to undergo shot blasting treatment to improve the adhesion of the coating. Through shot blasting, the surface oxide layer, oil stains, rust, and other substances can be cleaned, allowing the coating to firmly bond with the workpiece surface.

Improving fatigue life

Shot blasting treatment can eliminate stress concentrations and tiny cracks on the workpiece surface, thereby enhancing the fatigue life of the workpiece. This is crucial for parts that need to withstand high strength and frequent repeated loads.

Main application fields of industrial shot blasting machines

In the casting industry, an industrial shot blasting machine acts like a skilled craftsman, finely polishing and grinding castings without damaging their original shape and performance, making each piece shine brilliantly. The mold industry also benefits from the exquisite craftsmanship of the industrial shot blasting machine, which polishes molds according to different requirements, keeping them as smooth as a mirror to meet high production standards.

Steel plants and shipyards, the giants of the heavy industry field, also rely on the assistance of industrial shot blasting machines. Newly smelted steel and steel plates are often filled with burrs, affecting quality and aesthetics. The industrial shot blasting machine can easily solve this problem. The steel plates used in shipyards are rusted and affect shipbuilding quality, but the industrial shot blasting machine, with its efficient rust removal capability, ensures smooth progress in shipbuilding.

Additionally, industrial shot blasting machines play a pivotal role in automobile manufacturing, hardware electroplating, motorcycle parts, valve manufacturing, and bearing production. They meet the high polishing requirements of automobile parts, maintain the strength and shape of steel plates, make hardware electroplating parts cleaner, flatter, and smoother, easily handle the small and complex parts of motorcycles, finely polish valve parts, and clean impurities and burrs on bearing surfaces, enhancing their service life.

Even more noteworthy is that industrial shot blasting machines have demonstrated extraordinary strength in the maintenance of tunnels and bridges, contributing to transportation construction.

In conclusion, industrial shot blasting machines play a very important role in modern industry. They can improve product quality, enhance product performance, and extend product lifespan, thereby bringing more value and benefits to industrial manufacturing enterprises.

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro