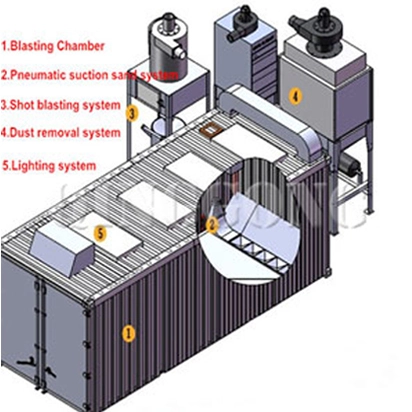

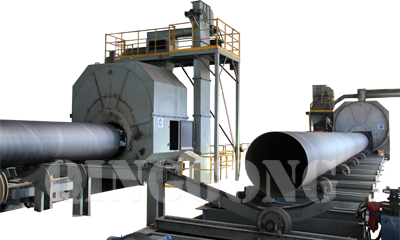

Sandblasting room is a kind of metal surface treatment machine. The difference with the shot blasting machine is the shot blasting method. Shot blasting machine uses the blasting turbine centrifugal force to projectile steel shot to the workpiece surface. Sandblasting room uses the air compressor to blow the steel shot in the sandblasting pot to projectile the steel shot to the workpiece surface.

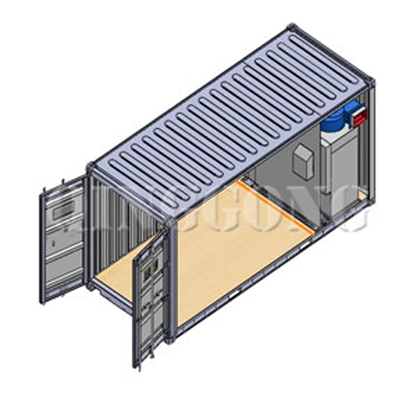

According to the customer’s workpiece parameters, our engineer gave them a set of 12000*6000*3000mm sand blast room with H type scraper recycle system. The H-type recycle system includes two scrapers longitudinal conveyor on each side of the room and one screw horizontal conveyor on the middle of the room. This type of recycling system can automatically reclaim about 60-90% of the abrasive. After sandblasting work, the worker pushes the abrasive into the scraper conveyor. The abrasive will transport to the screw conveyor automatically. And then will transport into the bottom of the bucket elevator, through the belt in the bucket elevator loading the abrasive into the separator to separate. At last, the unbroken abrasive will into the sandblasting pot recycled to use, and the broken abrasive and dust will discharge through the waste pipe.

For Qinggong Machinery quality is the most important impact, now let’s introduce some advantages of our sandblasting room:

1. The sandblasting room wall uses the sandwich panel with a noise attenuation layer, which thickness can be up to 50mm. The sandblasting room liner has a heavy-duty abrasion-resistant nature rubber plate, it can use for at least 5-8 years.

2. The sandblasting room wall also has a strong frame made from square tubes. And each wall has 2 meters. It can make sure the wall can not deformation during transportation and installation.

3. Light fixtures use high-efficiency LED lamps, using well-known brand chips, which is enable maximum utilization of the luminosity.

4. The blast room uses a multistage air separator. The separation effectiveness can be up to 99%.

5. Blasting system adopts the most advanced venturi blast nozzle, for the century nozzle, the material is boron carbide.

6. The dust collector we use America Donaldson technology cartridge filter to remove rust, the cleaning area can up to 15㎡, it can use 2-3 years. The dust collector with a sequence timer can set up the working time to clean the dust automatically.

Qinggong Machinery as one of professional sandblasting room and shot peening machine manufacturers will give you high-quality machines and cost-effective solutions. Welcome to contact us!

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro