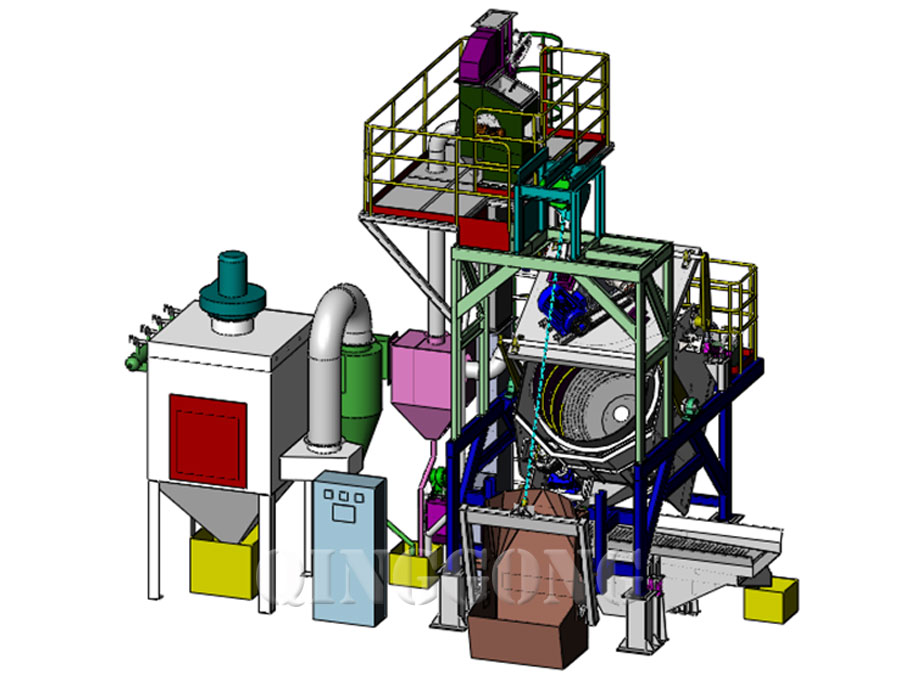

Features of Barrel Blast Machine

Efficient and uniform blast cleaning effect

Thin and small special parts can also be processed

Simple and accurate input and discharge

Simple maintenance

Advantages of Barrel Blast Machine

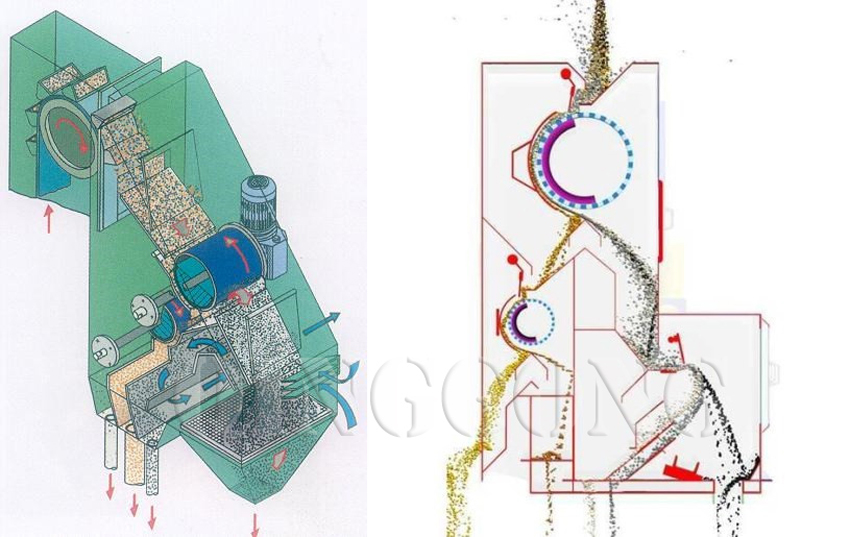

Using magnetic separator

Since the treatment is a casting, there is lots of sand on the surface of the workpiece. The wind separator alone is not enough to separate the molding sand ; the magnetic separation roller used by drum shot blasting machine make the rate of the sand separator more than 98%.

Environmental protection

The advanced secondary dust removal mode, including the first-stage cyclone dust collector and the secondary cartridge filters dust collector, can effectively make the dust emission concentration far below the standard to reach ≤50 mg/m3;

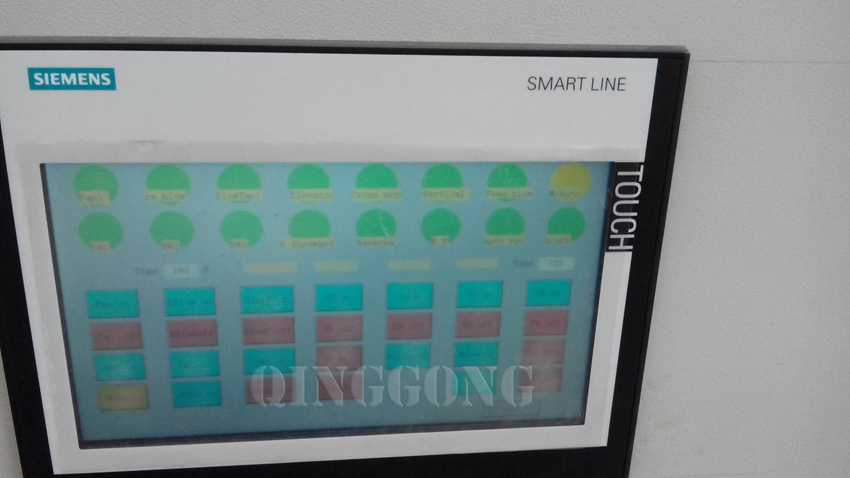

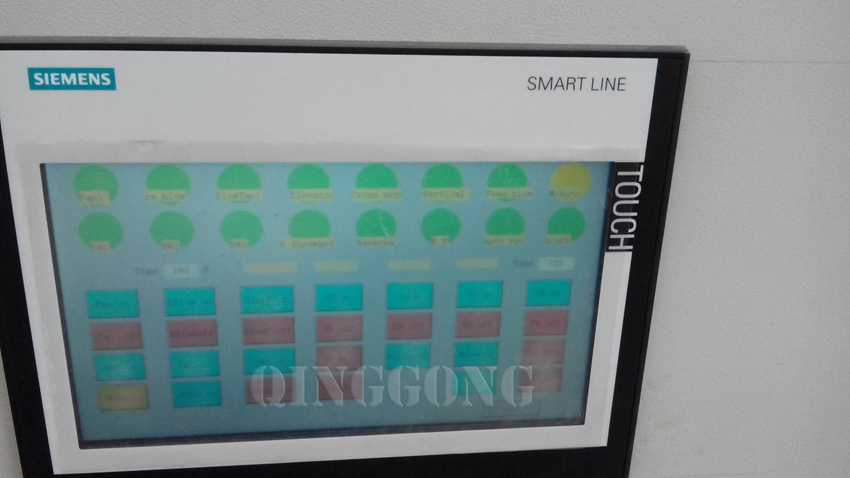

Advanced nature of electrical control

Centralized control with Siemens touch screen and PLC.

Applications of Barrel Blast Machine

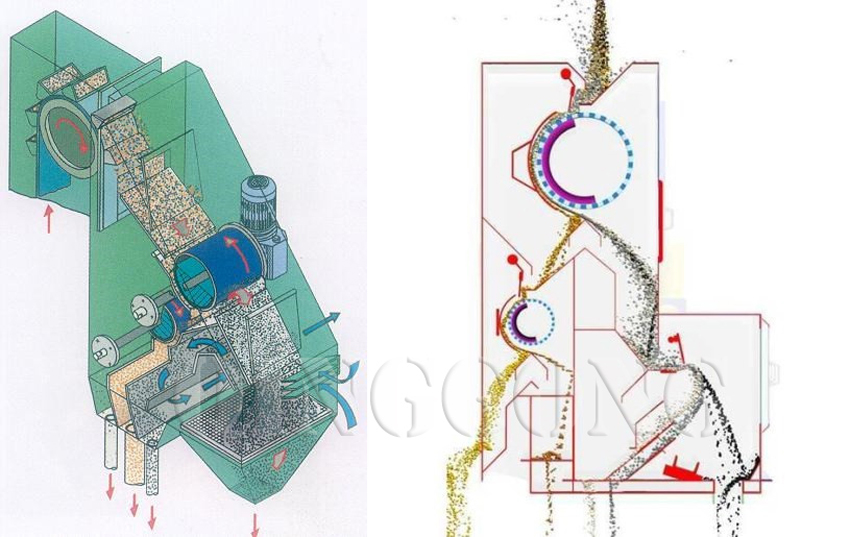

The Working Procedure of Barrel Blast Machine

Loading: The items to be cleaned or treated are loaded into a barrel or drum. This could include components, parts, or objects that require surface preparation, paint removal, or cleaning.

Abrasive Media: Abrasive media, such as sand, grit, or shot, is added to the barrel along with the items. The type and size of the abrasive depend on the desired finish and the material being processed.

Sealing the Barrel: The barrel is securely sealed to prevent the escape of abrasive media and to contain the blasting process.

Rotation: The barrel is set into motion, and it rotates, causing the items inside to tumble. This tumbling action helps to ensure uniform blasting of all surfaces.

Blasting Operation: Compressed air or another propellant is used to propel the abrasive media against the surfaces of the items inside the rotating barrel. This process of the working roto drum shot blasting machine removes contaminants, old coatings, rust, or other undesired materials from the surfaces.

Dust Collection: A dust collection system is often integrated into the machine to capture and contain the dust and debris generated during the blasting process.

Unloading: After the blasting cycle is complete, the barrel is stopped, and the treated items are unloaded.

A Video Display of Barrel Blast Machine

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro