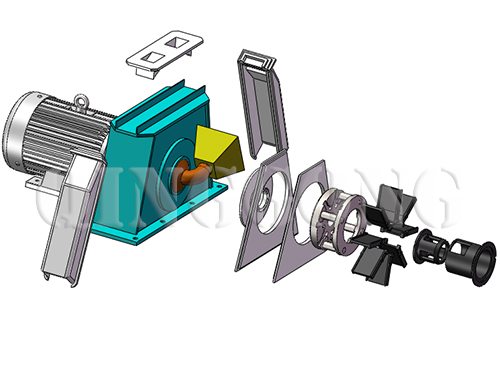

All kinds of shot blasting machine through the high-speed rotating blast turbine to throw steel shot to the surface of workpiece, has achieved required rust removal grade. Eliminating welding stress and improve the fatigue strength, increase film adhesion painting, provides ideal surface finish (SA2.5-3.0) for securing a continuous and effective bond between the steel surface and coat.

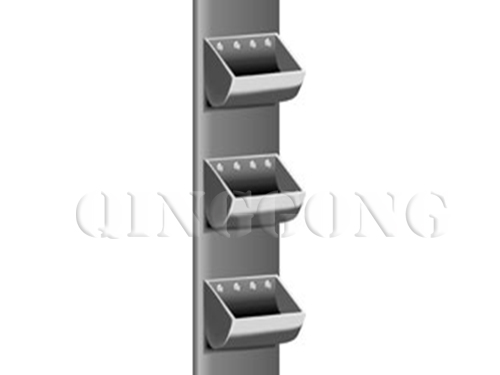

So the important thing is to adjust the blast turbines. Qinggong machinery according to customer's workpiece shape and size to design the position of the blast turbines, that determine the coverage of the abrasive.

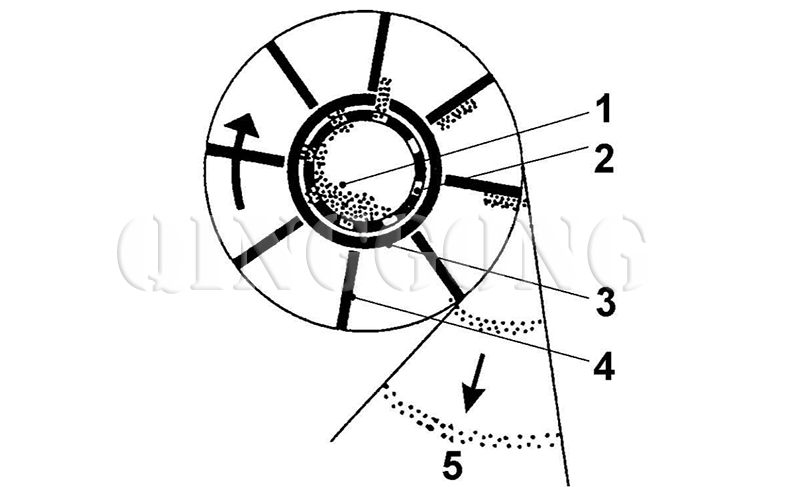

Abrasive① is accelerated by distributer②, enter the space between blades④ through control cage③. Each high speed rotating blade emits a stream of abrasive⑤

Abrasive stream is decided by types of abrasive, rotating speed, blade, control cage, etc. Abrasive stream is decided by control cage. On qinggong machinery's machine, it will have angle index label on the blast turbines, that guide the direction of control cage adjustment. Qinggong machinery will running all machine in factory, so will make a mark on the angle index label. Customer only need to loose bolts then turn groove on control cage to the mark on angle dial, that will have a good blast effect.

Please feel free to contact us if have any questions.

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro