Choosing suitable abrasive is important for shot blasting machine and sandblasting room. If the abrasive is not suitable for equipment, it will not only make the industrial shot blasting equipment damaged, but also lead to the blasting effect is unsatisfactory.

1. Hardness of steel shot: Steel shot that is too soft cannot produce suitable residual stress, and the impact force of low-hardness steel shot cannot be compensated by increasing the impact time. High hardness steel shot will cauese unsatisfactory surface morphology, increase the probability of fragmentation of the steel shot, increase consumption, and wear equipment, increase equipment maintenance costs. Steel shot hardness is high, cleaning speed is fast, but short life consumption is large, so the hardness should be moderate (about hrc40-50 appropriate) use the best effect

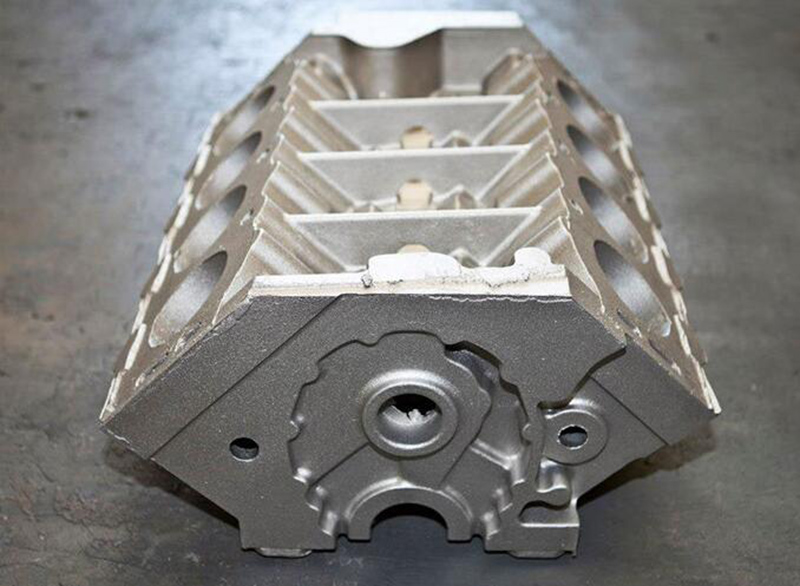

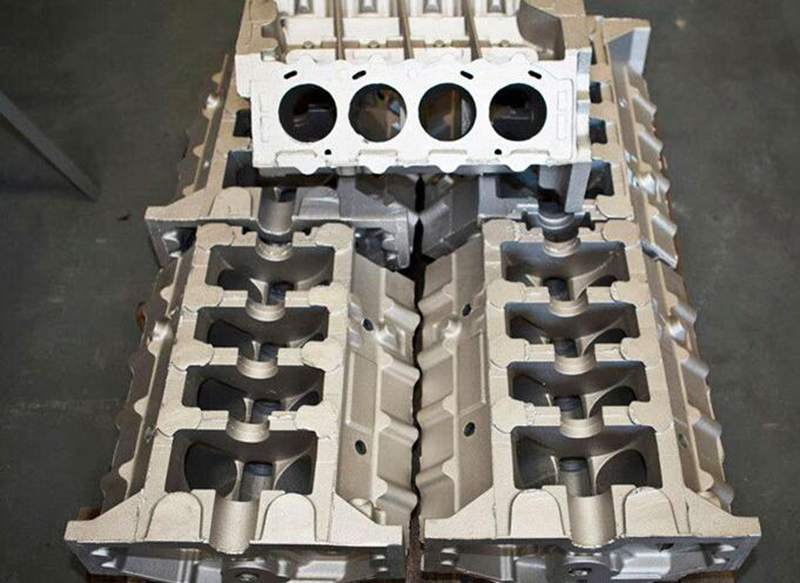

2. Types of the object items: Abrasive for shot blasting machine including steel shot, stainless steel shot, cut wire shot and others. Usually, stainless steel shot used for nonferrous metals; steel shot for common steel metal, such as h beams, steel plate, welding parts, castings, steel structures and other parts. The cleaning efficiency of cut wire shot is higher than steel shot, and the surface roughness is higher. Usually customer will mixture the steel shot and cut wire shot to use, that will easy to achieve the desired effect.

The blasting materials for sandblasting room, it depends on what kind of material customer need to blast cleaning, this is the first things for the blasting media's choice, for garnet, glass beads, steel shot, no problem for all of these.

But most customers prefer the steel shot, because it can cycle many more times than the garnet, glass beads, etc.

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro