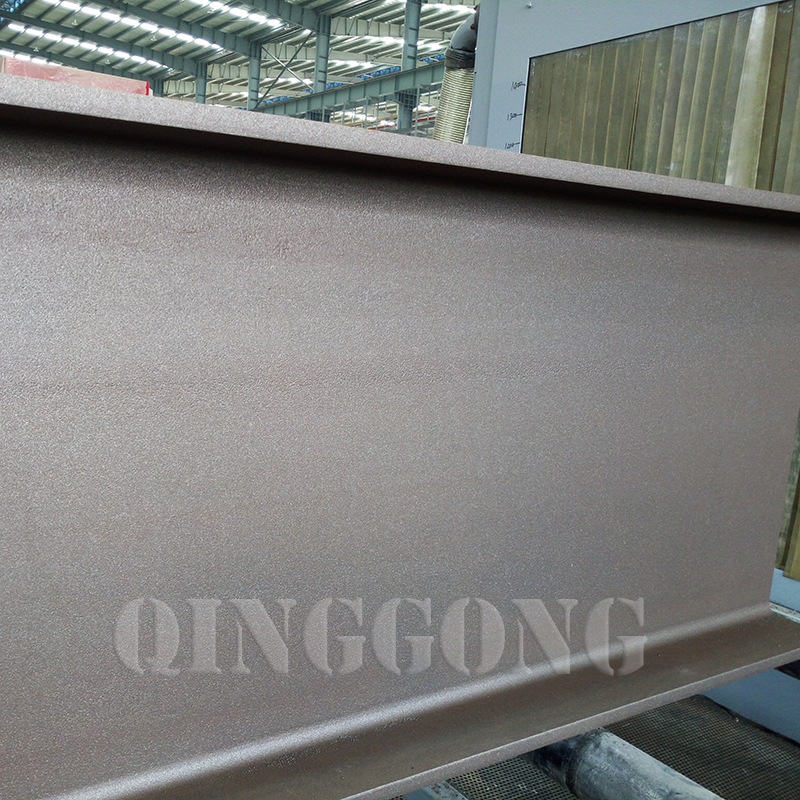

First of all, H Beam shot blasting machine is a kind of roller conveyor shot blasting machine. It is suitable for cleaning large quantities of HBeam shaped steel. Compared with other types of blasting machines, Qinggongcompany's H Beam shot blasting machine has the advantages of long service life, higher efficiency, better effect of rust removal, stable performance, conforming to the standard of discharge, and Small footprint. Currently, the H Beam of QG69 series shot blasting machine, which is the most popular model of Qinggong china sand blasting machine company, has significant rust removal effect and low price, which is popular in domestic and foreign markets. Qinggong Company will design different sizes of H beam shot blasting machines according to different requirements of customers, which is a piece of relatively excellent cleaning equipment in the market at present.

Working principle of h beam shot blasting machine

When the workpiece needs to be de-rusted, Workpiece Should be placed on the roller conveyor. The blasting machine is started on the electric control panel. When the blasting machine is detected by the infrared sensor, the blast wheel starts to work. The workpiece is derusting in the blasting chamber, then is transported out after rust removal is completed, the derusting work is completed. H beam shot blasting machine has a unique abrasive recovery system. When the h beam machine is working, the blasting turbines throw out the abrasive and fall into the screw in the bottom. It is transferred to the bucket elevator and then to the separator so that the ones that can continue abrasive to be used are transferred to the self-adaptive silo, while the ones that cannot be used are separated to the filter, and the dust is absorbed by the cartridge filter. Then the dust in the Cartridge filter was blown into the dust bag by pulse back blowing, and the abrasive recovery and dust removal were completed.

The composition of the abrasive cycle system

The abrasive cycle system is very important. For the sake of environmental protection and saving the production capital, the abrasive can be polished several hundred times, so it must be recovered after each use. An abrasive cycle system is made up of a screw conveyor, bucket elevator, and separator. In general, each shot blasting machine has 1 to 3 units screw conveyor system for conveying the finished abrasive cycle system. Abrasive pass to screw conveyor be delivered to bucket It is then into a separator.

It can still be used abrasive be delivered to abrasive silo,can not continue to use be is transported to the dust chamber。

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro