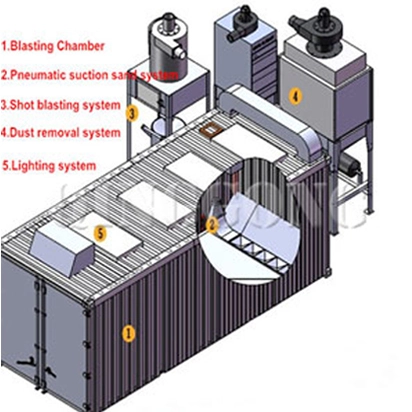

This is a super large size roller conveyor blasting machine, mainly used to blast the laser cutting machine bed and large size steel structures. The opening size of this machine is 4.5m*1.5m, loading capacity of roller conveyor is 2tons/m. In this way, large steel structure welding parts can be easily placed on the roller conveyor. The crane transports the workpieces to the 15-meter-long feeding roller. The roller conveyor adopts frequency conversion speed regulation. After adjusting to the suitable speed, the roller conveyor transports the workpiece to the shot blasting chamber. After the induction system senses that the workpiece enters the shot blasting chamber, the blast turbines will start working. The PLC control system makes operation very easy. Each part has detection and alarm devices, allowing complete automation. This shot blasting machine with 16 units high-performance direct-connected centrifugal blast wheels.

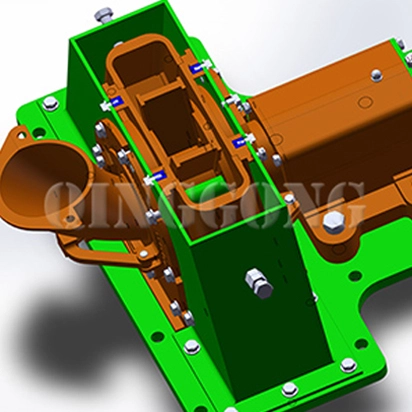

The efficiency is increased by more than 20% compared with conventional shot blasting machines. Of course, the projection angles of these turbines are designed strictly in accordance with three-dimensional projection simulations. This ensures the abrasive cover all surfaces of the workpieces and the workpiece can be thoroughly cleaned at one time when passing through the shot blasting area. The rollers in the projection area are equipped with wear-resistant sheaths, and both ends adopt unique three-layer protective sealing devices. The protective plate in the blasting area is made of rolled Mn13. This protection can ensure the service life of the equipment. In order to ensure the normal operation of the shot blasting machine, a continuous supply of steel shots is essential. This is inseparable from its abrasive circulation system.

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro