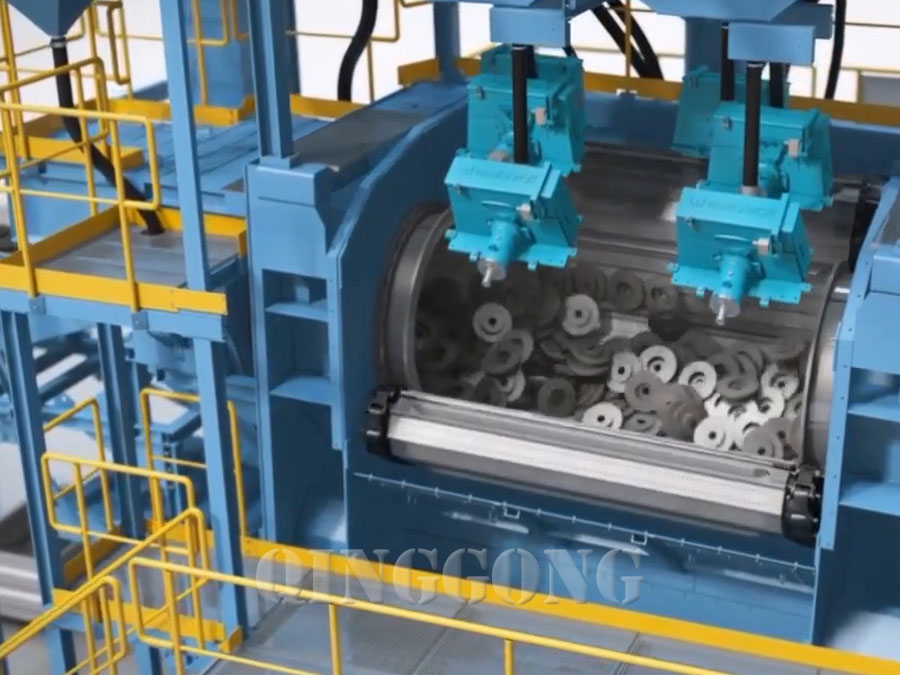

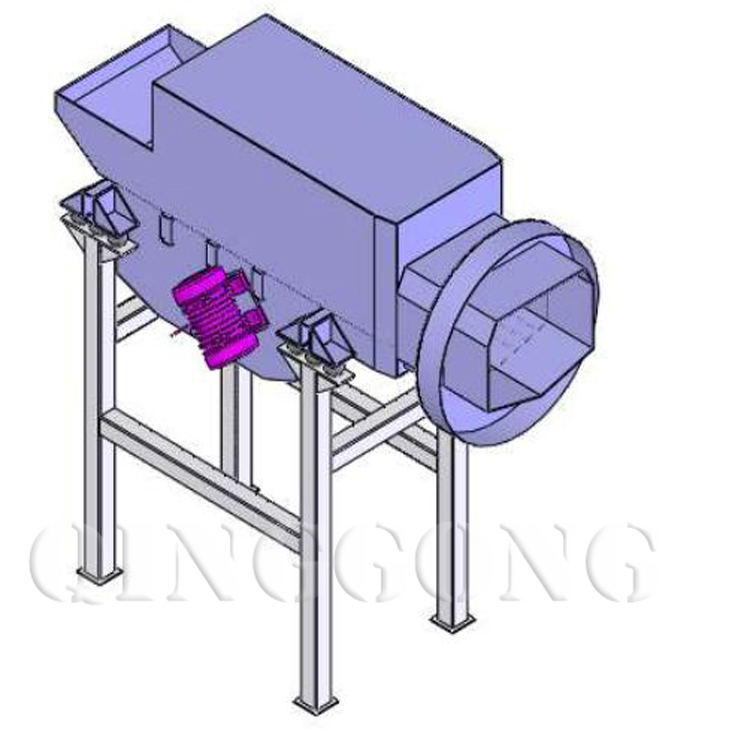

Continuous Tumble Pass-Thru Shot Blasting Machine Basic Specifications

Technical data | QGCT4-14 |

Single part maximum dimension | 700mm(L)×600mm(W)×500mm(G) |

Diameter of tumble belt | 1600mm |

Blast wheel types | KT36,38,42 and 50 |

numbers of blast wheels | 2/4/6 |

power of blast wheels | 22kw/45kw/50kw |

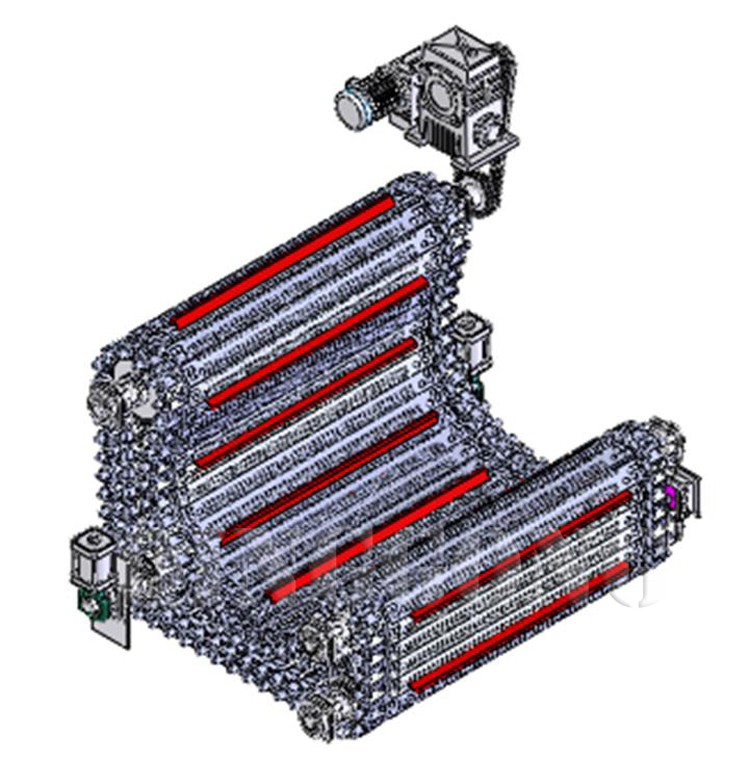

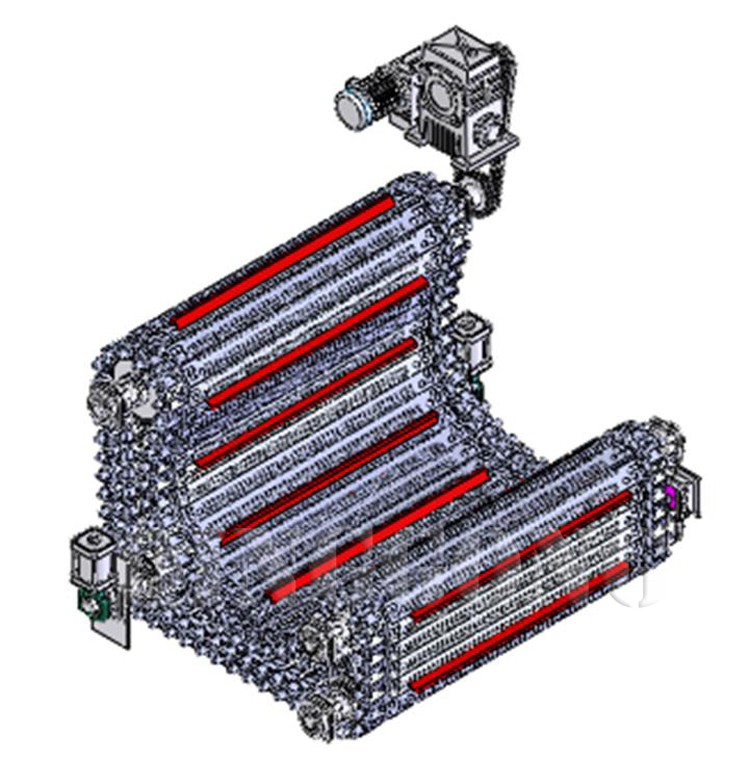

Tumblast belt

In order to greatly convenient the tumble of the workpieces, the equipment adopts the new patented technology of four-axis structure.

The thumb last belt adjustment uses the automatic cylinder tension device.

The tumble belt rotates speed is adjustable by a frequency inverter, which is adjusted according to the different workpieces actual conditions.

The belt is composed by the thickness of 20mm high manganese plate, the holes on the belt are cut by water jet cutter in order to prevent the deformation, the chainring adopted a unique structure so as to let the spattered blasting media drop into the abrasive reclaim system.

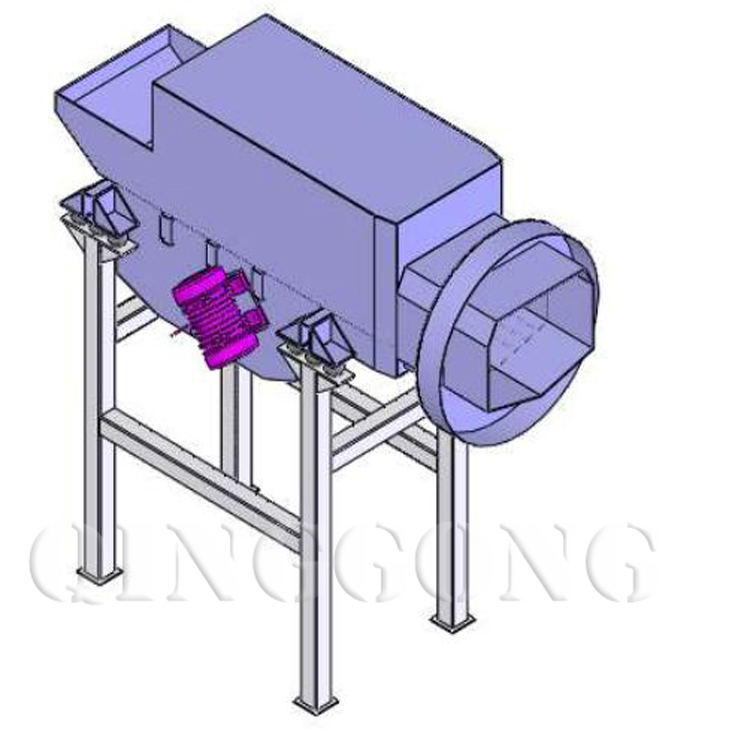

Loading and unloading of workpieces

The loading/unloading oscillating screen is to load

and unload workpieces into the blasting unit.

The loading capacity of the equipment is no more

than 200kg which is also a continuous type.

It is aimed for the conveying of the workpieces and

separating the big contaminants from the workpieces

Tumble belt rolling drum liner

The tumble belt rolling drum liner adopt high manganese steel plate, the rotation of the drum use the heavy-duty bearings to ensure the stability and durability of usage. The holes in the drum are cut by water jet cutter in order to convenient the abrasive reclaim.

Application

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro