Sandblasting room is the best shot blasting equipment for large-sized workpieces, complex workpieces and irregular workpieces. It is often used in the construction industry, foundry industry, shipbuilding industry, shot blasting industry, etc. If choosing a sandblasting room is a problem that many customers are concerned about, this article will help you solve the problem.

Firstly we should know the main designs for sandblasting room.

Usually have the fixed or removable.

For the fixed sandblasting room, Qinggong is proud to provide you with a high-quality, durable, and exceptionally low-noise body room.

This room is designed by using the Building Block. which is significantly reinforced by the use of welded strong square tubes. This robust construction approach ensures that, on one hand, the overall structural integrity of the house is markedly enhanced, making it exceptionally stable and reliable. Additionally, this design extended the service life of the house and ensured that it would maintain excellent performance over a long period of use. On the other hand, this innovative design also significantly reduces the time required for customer assembly, streamlining the setup process and enhancing user convenience.

The room is further equipped with a 50mm noise attenuation sandwich panel, which features a glass wool interlayer and an abrasion-resistant rubber liner. This combination not only effectively minimizes noise levels, creating a quieter and more comfortable working environment but also ensures the panel's durability and longevity. Moreover, the materials used are anti-flaming and innocuous, adhering to the highest safety standards and ensuring a safe and healthy environment for all users.

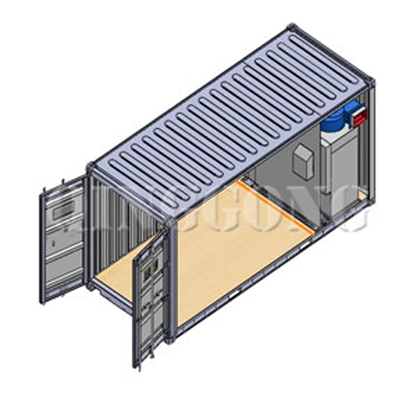

Another fixed choice is use the container as the room body.

The standard range of container rooms typically includes sizes of either 20 feet or 40 feet in length. These container rooms are particularly useful and effective in addressing and resolving various spatial challenges that may arise when a factory's available space is constrained or limited. Additionally, they prove to be highly beneficial in situations where a temporary site or location needs to be utilized for operational purposes. The shot blasting room, which is specifically designed based on the standard dimensions of transportation containers, offers a practical and cost-effective solution. By adhering to these standard sizes, it significantly reduces the design and manufacturing expenses that are commonly incurred during the production and construction of a traditional shot blasting room. This approach not only streamlines the manufacturing process but also ensures that the overall costs are minimized, making it a more economical and efficient option for businesses in need of such facilities.

The removable sandblasting room.

This sandblasting room integrates the container, pellet recovery system, dust collector, and electrical control of the sandblasting tank. It can be transported to the site by a flatbed truck and is ready for use within no more than 2 hours from installation. It is the best equipment for mobile operations in the field.

The features for this removable sandblasting room.

1.Convenient transportation: Based on the container structure, it can be easily transported by trucks, ships, etc. and can be quickly moved to different work sites. It is particularly suitable for outdoor construction, temporary projects, or scenarios where the work location needs to be frequently changed.

2.Installation is fast: No complex site infrastructure is required. Once on-site, simply fix and connect the water and electricity, and it can be put into use quickly, saving installation time and costs.

3.Space efficiency: The container itself serves as a closed space, providing the necessary enclosed environment for sandblasting operations. It also makes rational use of the internal space, integrating systems such as sandblasting equipment and dust recovery, with a compact structure.

4.Environmentally controlled: The dust recovery and treatment equipment equipped here can effectively control the dust and noise generated during the sandblasting process, reducing pollution to the surrounding environment and meeting environmental protection requirements.

5.Wide application range: It can be used for surface rust removal, oxide layer removal, and old coating cleaning of various workpieces such as steel, steel structures, ship components, and bridge components, meeting the surface treatment requirements of different industries.

The next step is need to know whether your plant whether can make the foundation.

Usually, in order to ensure the efficiency and stability of the entire workflow, it is necessary to build a corresponding foundation for the abrasive recovery system. This foundation can provide necessary support for the stable operation of the abrasive recovery system and ensure that its various functions can be smoothly realized. However, if the actual site conditions, financial situation, or other related conditions do not allow for the construction of such a foundation, don't worry. The cleaning engineer team, with their rich experience and professional knowledge reserves, will also carefully formulate customized solutions for each customer's specific situation. Whether it is the problem of limited site space faced by the customer or the difficulty of limited budget,QINGGONG engineer team can, with their wisdom and ability, find the most suitable solution for the customer.

Another crucial consideration is the selection of an appropriate abrasive recycling system.

In this regard, there are primarily two types of solutions available: manual and fully automatic.

If the workspace or room is particularly spacious and extensive, it is highly recommended to opt for a fully automatic abrasive recycling system. This choice ensures efficient and seamless operation, minimizing the need for manual intervention. However, if the space is more limited, customers have the flexibility to make a decision based on their specific requirements and the associated labor costs. Additionally, when it comes to the layout of the recycling system, there are several configurations to choose from, including the straightforward "—" one-line shape, the more complex "H" shape, and the versatile "U" shape. Each of these layouts offers distinct advantages and can be selected based on the spatial constraints and operational needs of the facility.

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro