Shot blasting and painting machines can be called a preservation line. That is a processing technology that does surface shot blasting and coated with a protective primer before the process.

The Workpiece of Shot Blasting and Painting Machine

The shot blasting and painting machine is suitable for steel plate, h beams, I beams, steel pipe, and other regular shape steel workpieces.

Application of Shot Blasting and Painting

After pretreatment, it can improve the corrosion resistance of the mechanical products and metal components, improve the anti-fatigue performance and prolong its service life; at the same time it also can optimize the steel surface process state and It is good for cutting and blanking of CNC cutting machine. In addition, because the steel before processing has a regular shape, it is conducive to mechanical derusting and automatic spray painting. Therefore, the use of shot blasting and painting can greatly improve the efficiency of blasting work; reduce the intensity of blasting work and pollution of the environment.

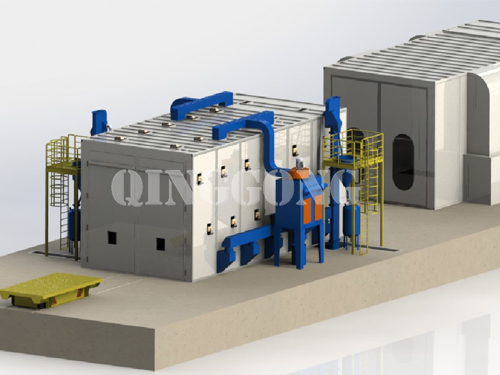

Constituent Part of Shot Blasting and Painting Machine

1. Inlet roller conveyor

2. Shot blasting machine

3. Abrasive cleaning up system

4. Dust collector for shot blasting machine

5. Painting room

6. Drying chamber

7. Outlet roller conveyor

8. Paint mist treatment system

.jpg)

Working principle of Shot Blasting and Painting

Steel plate is sent into the enclosed shot blasting chamber by the roller through shot blasting system firstly, using the high speed rotating impeller to throw the steel shot and cut wire shot onto the steel plate surface, impacting the steel plate surface to derust, the abrasive will into screw conveyor then through bucket elevator into the separator. The abrasive can be used in the storage bin, the duct will into the dust collector. Then using the brush, abrasive reclaim screw conveyor, and high-pressure abrasive blowing system clean out the dust and remaining shot on the surface of the steel plate. Then through a roller conveyor system get into the painting room. By high-pressure airless spray gun which is loaded on the top and bottom of spray car, spray coating primer to the surface of the steel plate. Automatic spray room is composed of frequency converter, motor, drive chain, traction chain, paint car, chamber, towline, and high-pressure airless spraying machine, etc. Then through the drying chamber to make the steel plate surface film to touch dry state. V type structure conveyor transport the steel plate into the drying room for drying after the spray painting. The V-type structure of conveyor synchronous running with the workpieces greatly reduces the contact area with the painted workpieces, which greatly avoids film damage during drying and transportation. The electric heater is arranged at the top of the outside drying room, through the heat exchanger, the heated air is sent into the drying room directly by the blower through the ducts system. Finally, be sent out and unloading by the conveyor system and hydraulic translation system. At the same time, the dust collector system and paint mist filtering system are in operation, to ensure that the workshop environment in a good position.

QINGGONG MACHINERY, as one of pro blasting supplies, offers customized solutions for integrated steel and preservation lines, based on extensive years of experience in this sector: Using our excellent engineering know-how, we design systems for your workpieces in line with your requirements to ensure that the desired level of quality is achieved, whilst optimizing process and operating costs.

Please do not hesitate to contact us if you are interested in the preservation line!

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro