H Beam Shot Blasting Machine Technical Parameter

| Type | unit | QGB600 | QGB1000G | QGB1500 | QGB2000 | QGB2500 | QGB3000 |

| Effective blasting width | mm | 600 | 1000 | 1500 | 2000 | 2500 | 3000 |

| Dimension of entrance(W×H) | mm | 800×550 | 1200×550 | 1700×550 | 2200×550 | 2700×550 | 3200×550 |

| Work speed to achieve cleaning of Sa2.5 ISO8501 | m/min | 0.5~3 | 0.5~3 | 0.5~3 | 0.5~3 | 0.5~3 | 0.5~3 |

| Number of wheels×power | kW | 4×7.5/11 | 4×11/15 | 4×11/15 | 6×11/15 | 8×11/15 | 8×11/15 |

| Wheel optional | kW | — | — | — | 4×15 | 6×15/18.5 | 6×15/18.5 |

| Abrasive initial filling capacity | kg | 2000 | 4000 | 4000 | 4500 | 6000 | 6000 |

| Processed length of the workpiece | mm | 1200~12000 | 1200~6000 | 1200~12000 | 3000~12000 | 2400~12000 | 3000~18000 |

| Foundation pit required |

| No | No | No | Yes | Yes | Yes |

The technical data is not binding and may be subject to change. Depending on the type of parts, production method, etc., further machine types and measurement specification sheets upon request.

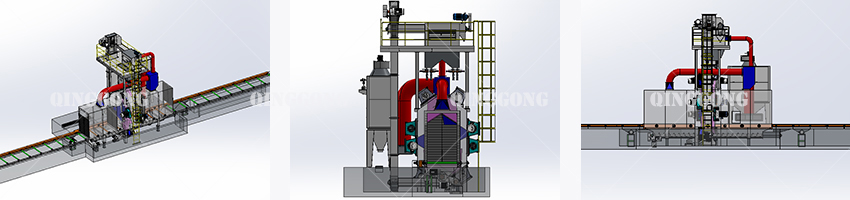

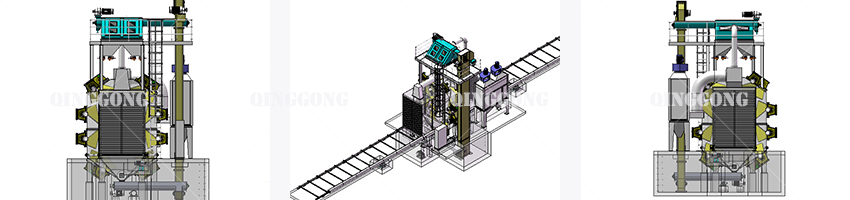

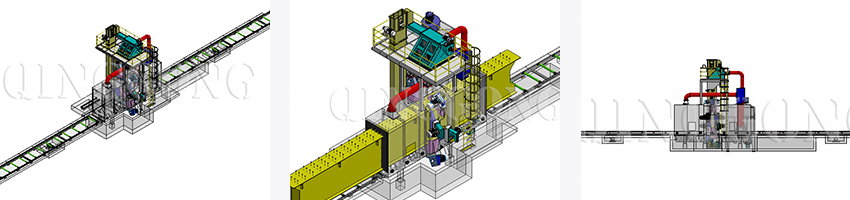

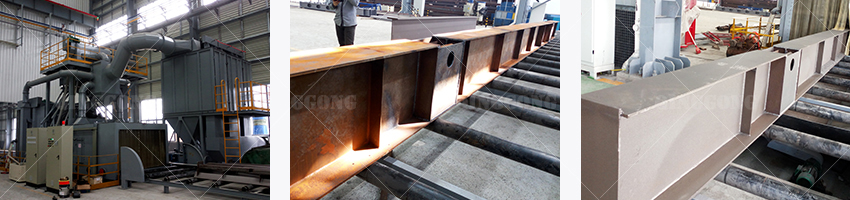

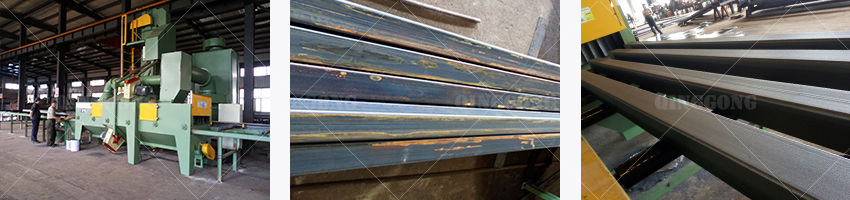

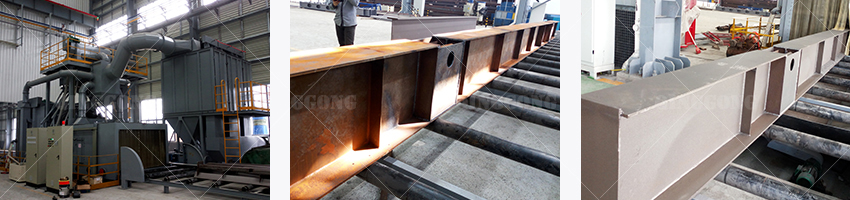

H Beam Shot Blasting Machine Details

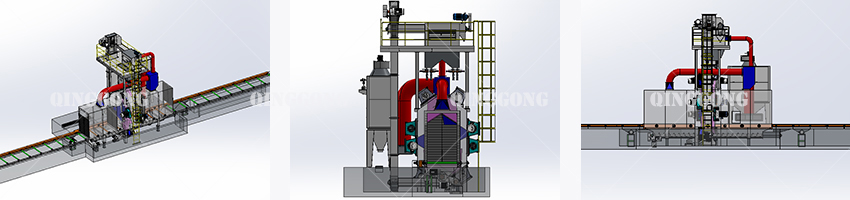

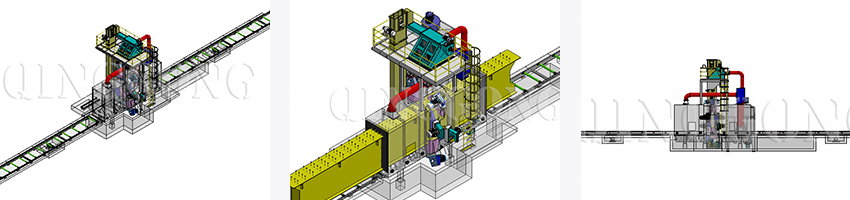

Abrasive recovery system:

H beam blasting machine system use a longitudinal screw conveyor to reclaim the used blasting media and contaminants into the crosswise screw conveyor, then into the bucket elevator and abrasive residue separator, and then the cleaned abrasive get into the storage hopper to recycle, the residual will get out of the recycling system from the air wash cleaner system.

Screw conveyor

The material of the screw conveyor is 16Mn, strong wear resistance.;

Screw conveyor is first welding and then processing, to ensure the concentricity of the screw conveyor.

screw conveyor two ends adopt labyrinth type superposition seal, high self-sealing performance, resistance to high pressure.

On the below of the screw conveyor has s manual emptying valve. If the screw conveyor is blocked, it can open the emptying valve to clear the abrasive that to run the structural steel shot blasting machine as soon as possible.

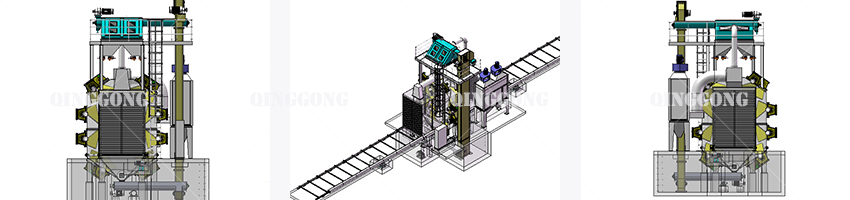

Abrasive residue separator

Our H beam cleaning equipment is applied for recycling shot/grit, which is to ensure high quality blasted surface and minimal abrasive shot. As the abrasive is so durable it is able to be recycled hundreds of times, resulting in an extremely low abrasive breakdown rate.

Critical to achieving this efficiency is the effectiveness of the abrasive recycling plant. Poorly designed or manufactured abrasive recycling systems will not correctly recycle the abrasive and are unable to maintain the correct abrasive working mix.

Our patented abrasive separator consists of an extended rotary separator drum that will totally remove all big clumps including big wast, scrap and paint chips etc. The abrasive is then fed through a gravity air wash separator where all dust, degraded abrasive and waste is drawn out of the good abrasive by an air current.

Only good, correctly sized abrasive is fed back to the abrasive storage hopper and blast pots for recycling.

Our patented abrasive cleaner ensures maximum recycling rates of the abrasive and high-quality surface finishing is achieved.

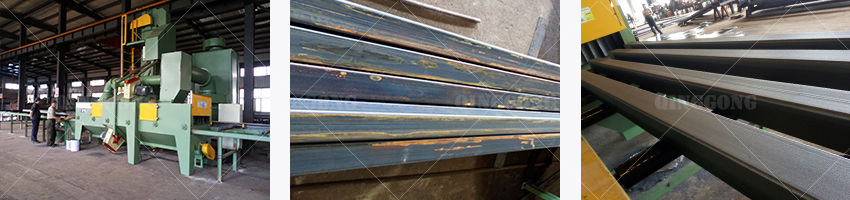

Applications of H Beam Shot Blasting Machine

H beam shot blasting machine is the most common machine in casting machinery, it can not only blast H steel, but also can blast steel structure, I beams, steel plate, steel sheets, steel tubes, steel pipes, steel bars, steel structures and other workpieces that can through the blasting chamber.

H Beam Shot Blasting Machine Advantages

Customized, meet workpiece and workshop requirements.

Factory outlet, bottom price

Wide application, 0ne machine with multiple workpieces.

Easy to operate, with manual / auto model.

High quality, 3 times acceptance

Acceptance three times before delivery

Equipped with environmental protection equipment, fully meet local environmental requirements

Services of H Beam Shot Blasting Machine

H beam shot blasting machine is non-standard machine, pls let us know below information then we will provided the best professional and cost-effective solution to you.

What kind of workpieces need to blast, only H beam or have other workpieces

The min.- max. size of the workpieces (L*W*H)

The maximum weight of the workpieces

The working capacity that need (how many pieces need to blast per day)

A Video Introduction to the Machine

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro