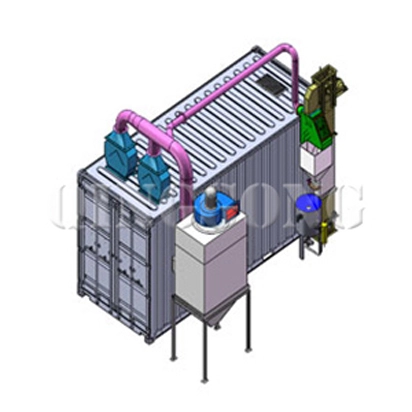

On August 21th, Qinggong Machinery has shipped a set of sandblasting room to Canada. The machine size is 19.5m*10m*6m with a crosswise scraper reclaim conveyor.

Sandblasting room is the most widely used machine to blast the workpieces. From the large steel structures to the small metal parts, from regular shape to irregular shap workpieces, the sandblasting room all can be clean. The very important point is that the sandblasting machine can protect the environment well. The dust collector installed on the sandblasting machine can filter 99.5% dust.

Now let Qinggong Machinery introduce some details about the sandblasting room as below:

1. Sandblasting room chamber

The sandblasting room wall is made of steel tube and sandwich panel, which is uses the steel tube to make a frame as the base and fabrication with the 50mm thick sandwich panel. The sandwich panel can reduce the noise from outside and can also be anti-flaming. Qinggong sandblasting room wall adopts the modular design and every frame with the sandwich panel are about 2 meters wide. That design not only can make the room stronger that can not be easily deformation but also let more convenience during transportation and installation.

In the sandblasting room chamber, we also use the heavy duty abrasion resistant rubber sheet to protect the sandwich panel to avoid the damage of the abrasive during the sandblasting. In normal working conditions (6 days a week and 8 hours a day) the service life of the rubber sheet can be more than 7 years.

The light fixtures we use are the Led lamps, which are much higher than the halogen lamp on the brightness and service time.

2. Floor reclaim system

In Qinggong Machinery, we have five type of floor reclaim system for your choice.

a. Sweep/Shovel chute type reclaim system. This type of reclaim system is the most economical and simple one. It is suitable for the low production company. After sandblasting, need the workers to push the abrasive into the pit, which is connected with the bucket elevator.

b. Single screw/scraper reclaim system. This type of reclaim system is the most common one, most customers can choose this type. It like its name, use single screw/scraper connect with the bucket elevator. The worker only need to push the abrasive into it, then the abrasive will recycle in the whole machine.

c. L type reclaim system. This type of reclaim system has one crosswise screw/scraper conveyor and one longitudinal screw/scraper conveyor. The worker only needs to push the abrasive into longitudinal screw/scraper conveyor, then the abrasive will recycle in the whole machine. The cleaning efficiency can be up to 40-70 percent.

d. H/U type reclaim system. This type of reclaim system has one crosswise screw/scraper conveyor and two longitudinal screw/scraper conveyors. The worker only need to push the abrasive into longitudinal screw/scraper conveyor, then the abrasive will recycle in the whole machine. The cleaning efficiency can be up to 60-90 percent.

e. Full floor type reclaim system. This type of reclaim system is the fully automatic system, which can be sandblasting continuously. The full floor all uses the scraper conveyor, the abrasive falls into the scraper conveyor and the scraper will transport them into the recycle system without any manual operations. The cleaning efficiency can be up to 100 percent. It is suitable for the high production company.

3. Sandblasting machine system

Sandblasting machine system including the sandblasting pot, hose, and gun. Although this is the small part of the sandblasting room, it is the most important part.

Usually, a set of the sandblasting room for sale is equipped with one or two sandblasting pots, which need to according to the production of the company. The sandblasting pot adopts the air compressor to projectile the abrasive. The abrasive through the hose and then arrive at the venture nozzle at the other end and hit on the workpiece surface.

4. Abrasive recycling system

Abrasive recycle system composed with the bucket elevator and separator. When the abrasive is into the bucket elevator, the hoppers will bring the abrasive from the bottom of the elevator to the top of the elevator. And then throw the abrasive into the separator. Qinggong machinery adopt the three-level air wash to separate the abrasive and the dust, which can achieve an abrasive separation effect of up to 99%.

5. Dust collector system

The dust collector system have cartridge filter, fan motor, and dust collector box. The dust collector connects with the air compressor. It uses the pulse-jet principle and an air shock valve with a timing device to clean the dust on the cartridge filters regularly. The filter material we use is the Donaldson Technology, the filter efficiency can be up to 99.5%.

Qinggong Machinery is the most professional shot blasting machine and sandblasting room manufacturer. We have 46 years' experience with these machines. Quality is the most important thing for us to get survive for a long time. If you are interested in the shot blasting machine or sandblasting room, please do not hesitate to let me know. Our engineering team will give you the most professional and cost-effective solutions.

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro