1. About the roller shot blasting machine

Shot blasting machine is a kind of modern machinery used in many fields. According to different application fields, this kind of shot blasting machine is divided into many kinds. Roller shot blasting machine is one of them. Although this type of shot blasting machine is different from the old-fashioned shot blasting machine, its working principle has not changed, but the processing of the workpiece is more subdivided.

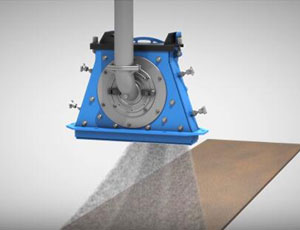

The roller shot blasting machine mainly uses a high-speed rotating impeller to throw projectiles to the drum, which is a continuous turning process. Then in such a process, it can achieve the purpose of cleaning the workpiece. In terms of the field, such a machine still belongs to the scope of casting machinery, and its role is to process the workpiece, but it has more requirements for the workpiece and its role is more detailed.

2. What kind of workpiece is suitable for using roller shot blasting machine?

The drum shot blasting machine is mainly used for sand removal, rust removal, descaling and some surface strengthening of workpieces under 15 kg. Although its function is still the same as that of the shot blasting machine, the requirements for the workpiece are different. The old-fashioned shot blasting machine does not have so many requirements for the workpiece, but this drum shot blasting machine has some requirements. The drum shot blasting machine is more suitable for cleaning some parts that are not afraid of impact and scratches. We know that some of the current workpieces are used in some precision fields, so the requirements for the workpieces are getting higher and higher.

But this kind of workpiece will inevitably produce some defects after it is produced, such as oxide skin, which is an inevitable defect. If it is not cleaned up, some failures may occur in the application area. Although this kind of drum shot blasting machine has a lot of harsh processing requirements, its effect is undoubtedly very good, and it can effectively ensure that there are no problems with the processed workpiece.

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro