The characteristics of the channel shot blasting machine is that its quality is better than other types of shot blasting machines. Therefore, its useful life is relatively long, and its function is also very powerful. Because of its high quality, this type of machine is also very high in sales of its type. The large increase in market demand has also greatly increased the supply of many companies.

According to the different raw materials used to make it, the market price is set, and the functions of machines of different prices are certainly different. Different fields require channel steel shot blasting machines made of different materials. Customers must consider which kind of channel steel shot blasting machine they really need. Choose your own machine according to your actual needs. It is the ability to maximize its role.

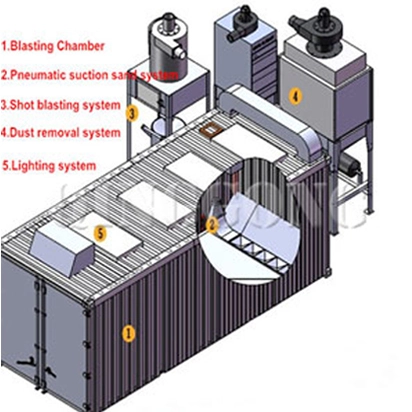

Different from bricks shot blasting machine, this machine opening size is 1000mm wide and 500mm height, with 4 units blasting wheels. This customer use the machine to clean the steel channel and other parts. The projection angles of all blasting wheels are designed by engineers, which use 3D simulations based on customer workpieces.

Channel steel shot blasting machine specification model:

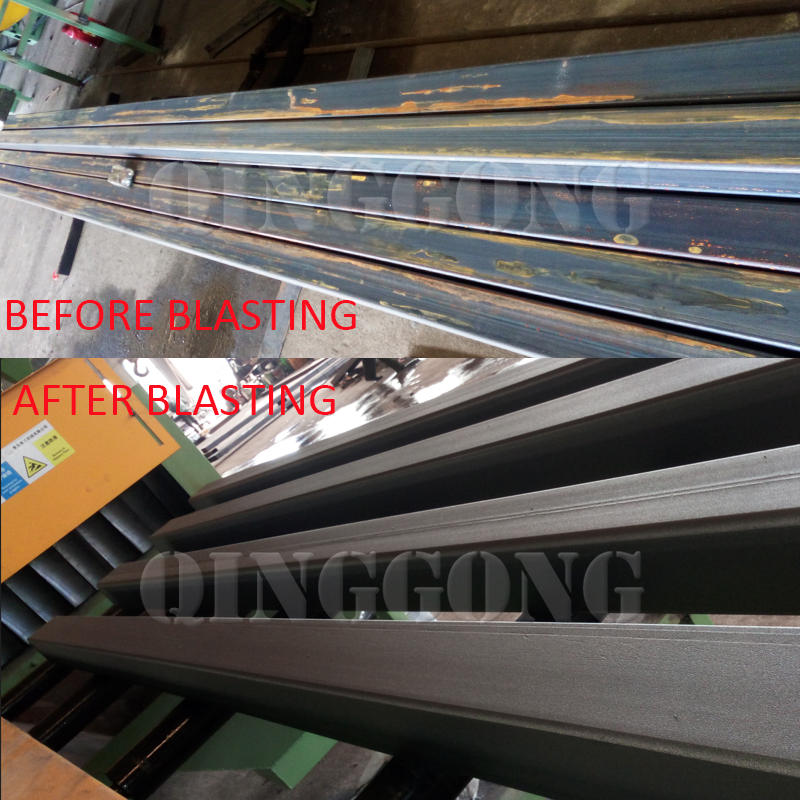

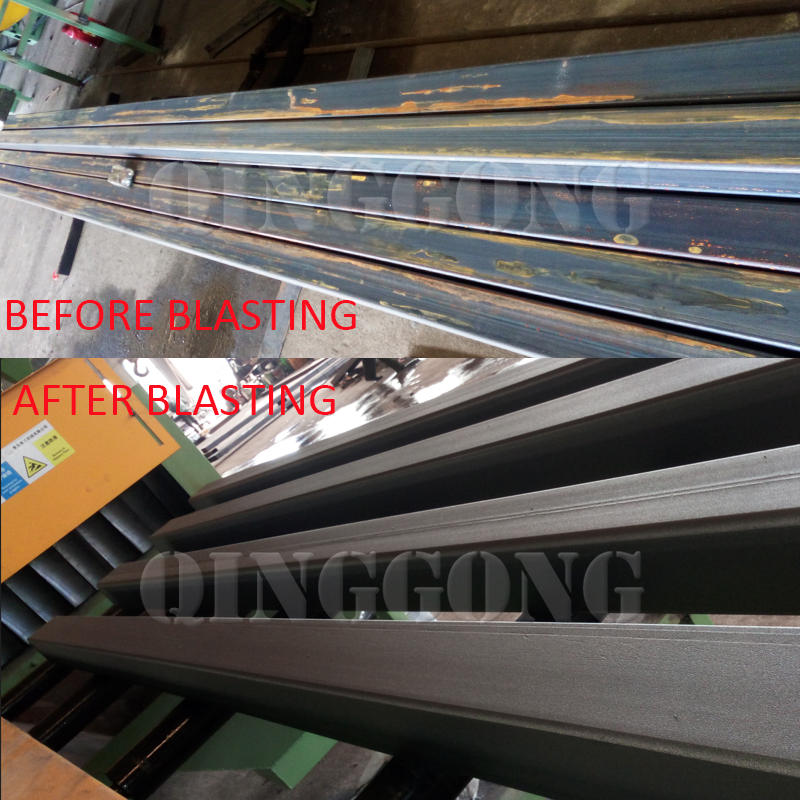

The channel steel or profile is fed into the projectile area of the blasting chamber by the electrically controlled adjustable speed roller conveyor during the channel steel shot blasting machine. The whole body of the steel shot blasting equipment is subjected to strong and dense projectiles from different coordinate orientations. Rubbing, so that the scale, rust layer and its dirt on it quickly fall off, the surface of the steel obtains a smooth surface with a certain roughness, and the workpiece is loaded and unloaded on both sides of the inlet and outlet.

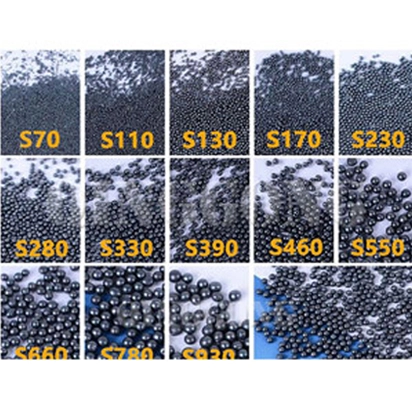

The projectiles and rust dust falling on the channel and the profile are purged by the purging device, and the sprinkled mixture of the ball and dust is transported from the recovery screw to the chamber funnel, and the vertical and horizontal screw conveyors are collected in the lower part of the bucket elevator and then lifted to the machine. In the upper separator, the separated pure projectile falls into the separator hopper for blasting.

Dust generated in the shot blasting is sent to the dust removal system by the exhaust pipe, and the cleaned air is discharged into the atmosphere, and the particulate dust is captured and collected.

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro