When it comes to surface preparation and cleaning, satellite table shot blasting machines have emerged as a reliable choice in various industries. These machines are widely used for removing rust, scale, paint, and other contaminants from different surfaces, ensuring a smooth and clean finish. However, with a multitude of options available in the market, it can be challenging to select the right satellite table shot blasting machines that meet your specific requirements. In this blog, we will discuss the key features that you should consider before making a purchase decision.

Machine Size and Capacity

One essential factor to consider is the size and capacity of the satellite table shot blasting machines. The machine's size should align with the available workspace and the nature of the items you intend to clean. Additionally, choose a machine with adequate capacity that matches your production needs. Different models offer varying sizes of satellite tables to accommodate different workpiece sizes. Assess your requirements carefully to ensure that the machine you select can effectively handle your workload.

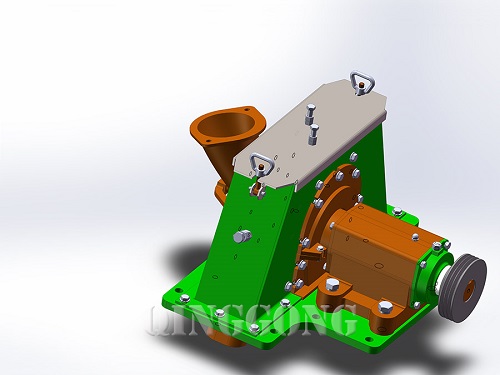

Shot Blasting Wheel Configuration

The shot blasting wheel configuration plays a crucial role in determining the efficiency and effectiveness of the machine. The number and arrangement of the shot blasting wheels impact the coverage and uniformity of the blasting process. Depending on the application, you can choose a single wheel or multiple wheel configurations. Multiple wheel configurations offer better performance and shorter cleaning cycles. Consider the specific requirements of your workpieces and select a machine with the appropriate shot blasting wheel configuration accordingly.

Dust Collection System

Efficient dust collection is vital for a safe and clean working environment when using satellite table shot blasting machines. It is crucial to select a machine with a reliable dust collection system to eliminate hazardous airborne particles generated during the blasting process. An efficient dust collection system not only ensures worker safety but also reduces the cleanup time and maintenance efforts. Look for machines with proper dust containment and ventilation systems to minimize environmental pollution and maintain a healthy workplace.

Control Systems and Automation

Modern satellite table shot blasting machines come equipped with advanced control systems and automation features to enhance productivity and ease of operation. These systems allow for precise control of parameters such as abrasive flow, blast time, rotation speed, and table indexing. Automation features like touchscreen interfaces, programmable options, and remote control capabilities simplify machine operation and offer greater control over the blasting process. The choice of control system ultimately depends on your specific needs and the level of automation desired.

Investing in a satellite table shot blasting machine requires careful consideration of various features to ensure optimal performance, efficiency, and cost-effectiveness. Prioritize factors like machine size and capacity, shot blasting wheel configuration, dust collection systems, and control systems when making your decision. By selecting the right machine tailored to your specific application, you can achieve superior surface cleaning results and streamline your operations efficiently. Always remember to conduct thorough research, evaluate multiple options, and consult with industry professionals before making a final decision.

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro