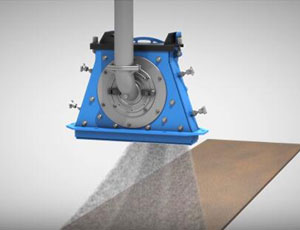

Ⅰ. The scope of application of the crawler shot blasting machine

The crawler shot blasting machine is suitable for cleaning the surface of various parts. All kinds of metal casting surface sticking sand cleaning, ferrous metal parts surface rust removal, stamping surface and burr blunt, forging and burr heat treatment workpiece surface treatment and spring surface oxide scale removal and surface grain refinement, etc. It is achieved through the shot blasting process of this series of equipment. Crawler shot blasting machines have a wide range of applications, including foundries, heat treatment plants, motor plants, machine tool parts factories, bicycle parts factories, power machine factories, auto parts factories, motorcycle parts factories, non-ferrous metal die-casting factories, etc. The workpiece after shot blasting can obtain good material quality, and can also become the pre-process of blackening, bluing, passivation and other processes on the surface of metal parts, and at the same time can provide a good base surface for electroplating and paint finishing. After shot blasting by the crawler shot blasting machine, the workpiece can reduce the tensile stress and refine the surface grains, thereby strengthening the surface of the workpiece and increasing its service life.

Ⅱ. The processing requirements of the crawler shot blasting machine

The construction inspection standard of the crawler shot blasting machine is: 100% cleaning to achieve no floating slurry on the surface; clean; no floating dust; no pollutants; the surface defects of the crawler shot blasting machine should be repaired; the shot blasting cleaning should reach a smooth surface after treatment, reaching 100% wound surface; aggregate exposed; no loose aggregate; roughness: CPS control version SP3 SP5; or sand laying method 0.4-0.8. The processing technology of the crawler shot blasting machine has been incorporated into the construction technology specifications of many provinces. However, there are uniform standard requirements for the protective coating of concrete surfaces.

Ⅲ. Maintenance and maintenance of the crawler shot blasting machine

1. After each work shift, the industrial shot blasting equipment should be cleaned once; 2. The guard plate in the cleaning room and the wear condition of the wear parts such as the directional sleeve and the shot blasting wheel in the shot blasting machine should be checked frequently. If it is serious, it should be replaced immediately; 3. It should be lubricated regularly according to the regulations, and the crawler shot blasting machine should be regularly checked for flexible rotation; 4. Regularly check the transmission parts, clean the parts, and replace the worn parts; 5. The crawler shot blasting machine During inspection and maintenance, the power supply must be cut off to avoid accidents; 6. The wear-resistant guard plate of the cleaning room can be replaced regularly according to the wear and tear. When replacing the guards, the installation gap between the guards should be controlled within 2 mm.

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro