Recently QINGGONG Machinery has successfully delivery a hanger type shot blasting machine for our domestic customer. Let me give a brief introduction of this product.

Hanger type shot blasting machine has a high production efficiency and a large flexibility span. It is an ideal cleaning and strengthening equipment and it is easy to operate. It is widely used in the surface cleaning or strengthening treatment of small and medium-sized castings and forgings in the casting, construction, chemical, electrical, machine tool and other industries.

At present, the shot blasting machine for sale is widely used. Whether it is manufacturing or processing production, the shot blasting machine will be used to handle the overall utilization rate as high as about 80%. The shot blasting adopts the method of high-speed rotating impeller to throw out steel shots and small iron shots. High-speed impact on the surface of the workpiece to achieve strengthening and cleaning effects. Almost all steel castings, gray castings, malleable iron parts, ductile iron parts, etc. of the hook type shot blasting machine must be shot blasted. This is not only to remove the oxide scale and sticky sand on the surface of the casting, but also an indispensable preparatory process before the quality inspection of the casting. For example, the casing of a large gas turbine must be subjected to strict shot blasting before non-destructive inspection to ensure the inspection result. reliability. The shot blasting machine is a hook type shot blasting machine that is transmitted through the kinetic energy of the motor reducer. The hook type shot blasting machine is driven by a supporting roller to rotate the drum smoothly at a speed of 3r/min to make the hook type shot blasting machine drum The parts in the body roll gently, allowing the parts to be impacted and scraped by shot blasting at different angles, so that not only can the rust, sand and dirt on the surface of the workpiece be removed, but the hook shot blasting machine can also improve The internal stress of the workpiece improves the surface quality of the workpiece, achieves the purpose of cleaning and strengthening, and improves the fatigue strength of the workpiece.

Double hook type shot blasting machine advantage:

The international advanced cantilever centrifugal blast turbines with large shot blasting volume and high shot speed is adopted to improve the cleaning rate and cleaning quality.

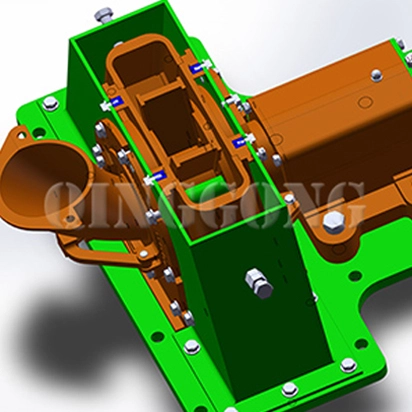

All drawings of the simulated projectile diagram and shot blasting machine are drawn by computer-aided design (CAD) and the selection and layout of the blast turbine are more reasonable.

The use of a pit-free structure not only saves the construction cost and time of the pit foundation, but also solves the problem of rust and agglomeration of shot sand in the bucket elevator caused by the user due to the water in the pit. The hook has the functions of lifting, running and indoor rotation.

The blasting chamber adopts high chromium guard plate, the service life is greatly improved and the appearance is beautiful and easy to replace.

The double hook shot blasting machine suitable to lift workpieces with a weight of less than 3 tons. Double hook shot blasting machine has large volume, high cleaning efficiency, large effective room space, compact structure, no pit form, no special requirements for the shape and structure of the cleaning workpiece and one machine can be used for multiple purposes.

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro