The sandblasting room designed by QINGGONG Machinery can complete a wide range of blasting jobs for those big and irregular workpieces. Traditional sandblasting equipment design can't be used to deal with parts in different shapes. However, our sandblasting room design is completed by professional engineers with rich experience. Our objective is to meet customers continuing demands for sandblasting business. The sandblasting room can blast big and irregular workpieces from all angles and make them clean. We want to make sure that our sandblasting room for sale can perform your job efficiently and economically.

The wall of the sandblasting equipment body uses a noise attenuation sandwich panel with glass wool interlayer and abrasion-resistant rubber liner. The rubber liner also has the noise attenuation function.

The sandblast room wall is strengthened by welded strong square tubes which ensure they will not deformation during transportation and installation. The grinding and the painted square tube will be far enough to resistant the corrosion by the natural environment.

The cargo door and roof are built-in welded profiles and have closed in steel plates, and it internally assembled with abrasion-resistant rubber (up to 5mm). an exclusive sealing system prevents the loss of abrasive materials and makes the closing of the doors possible without effort.

Light fixtures use high efficiency LED lamps, which enables maximum utilization of the luminosity. The fastening system of the blasting room allows easy removal for maintenance.

The system of sandblasting equipment adopts the most advanced venturi blast nozzle. For the venturi nozzle, a new combination of aluminum and polyurethane adds proven advantages in weight balance, strength and shock absorbent features not found in metal cased nozzles. The long venture design of the abrasive sandblasting machine will maximize production requirements as well as give added abrasive impact when needed for tough, hard to clean surfaces.

The abrasive recovery system for blasting room have 4 parts: floor recovery, bucket elevator and separator.

Sandblast room recovery system use floor recovery system to reclaim the used blasting media and contaminants into the bucket elevator and then into the air wash cleaner system, and then the cleaned abrasive get into the storage hopper to recycle, the residual will get our of the recycle system from the separator.

Sweep/Shovel Chute Type

Sweep/Shovel Chute Type

Sweep/ shovel chute type is the most economical abrasive reclaim system, which is only appropriate for low production operations.

This is the simplest reclaim system, but need to push the abrasive into the recycle system manually after blasting work.

This blasting room recovery system almost no need foundation pit, no damage to the ground.

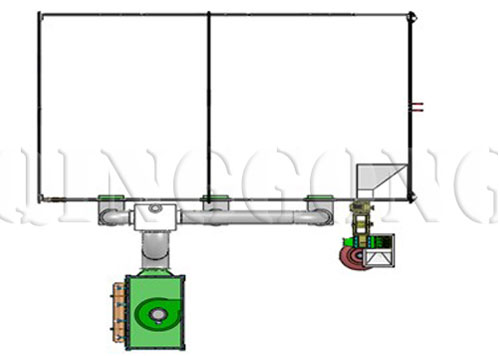

Single Screw or Scraper Partial Reclaim System

Single Screw or Scraper Partial Reclaim System

The most economical floor design is available. The system contains a screw conveyor or craper conveyor, heavy-duty screw belt and bucket elevator,air-wash separator, perforated plate rotary drum separator and oversized abrasive storage hopper with a caged man ladder and handrail. This can be expanded to an "H", "U", or full floor reclaim system, which is best suited for low to medium production levels.

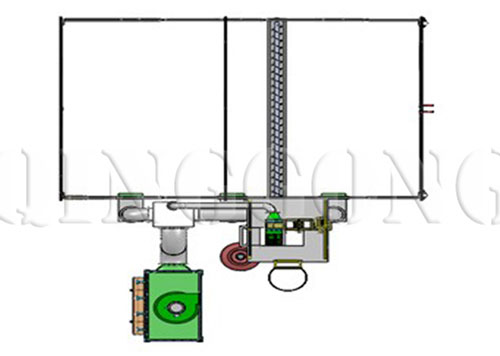

"L"- Shaped Partial Reclaim System

"L"- Shaped Partial Reclaim System

Adds one longitudinal conveyor along one sidewall of the blast room allowing the abrasive delivered from the blasting nozzle, which is either blown or rebounded off the workpiece, to strike the side walls and fall into the conveyors, automatically reclaiming approximately 40-70 percent of the blast media. The reclaiming abrasive on the blast booth floor is pushed into the screw or scraper conveyors assemblies at the end of the work shift. The "L" shaped floor design is typically used in a “flow-through” room configuration where heavy workpieces and/or material handling devices can drive into the room. This is best suited for low to medium production.

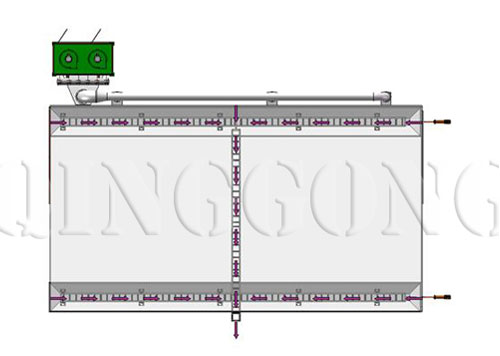

"H" - Shaped Partial Reclaim System

"H" - Shaped Partial Reclaim System

Adds two longitudinal conveyors along each sidewall of the sandblast room allowing the abrasive delivered from the blasting nozzle, which is either blown or rebounded off the workpiece, to strike the side walls and fall into the conveyors, automatically reclaiming approximately 60-90 percent of the blast media. The reclaiming abrasive on the floor is pushed into the screw or scraper conveyors assemblies at the end of the work shift. The “H” shaped floor design is typically used in a “flow-through” room configuration where heavy workpieces and/or material handling devices can drive into the room. This is best suited for medium to high production.

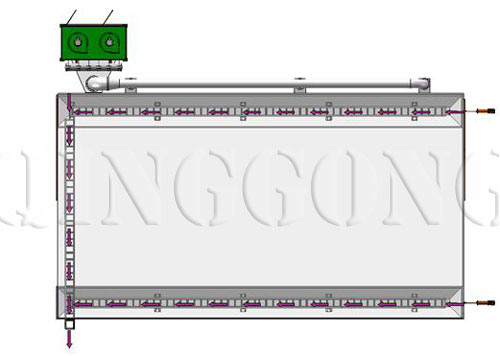

"U"- Shape Partial Reclaim System

"U"- Shape Partial Reclaim System

Adds two longitudinal screw or scraper conveyors assemblies along each wall of the blast room and positions the cross screw or scraper conveyors along the back wall of the blast room. This allows the abrasive delivered from blasting nozzle, which is either blown or rebounded off the workpiece, to strike the sidewalls and back wall of the blast room and fall into the reclaim system, A “U”- shaped floor design will automatically reclaim 60-90 percent of the blast media. The remaining abrasive on the floor is pushed into the metered shed plate screw assemblies at the end of the work shift, The “U”-shaped floor design is typically used in an “in-out” room configuration where heavy workpieces and/or material handling devices can drive into the room. This is best suited for medium to high production

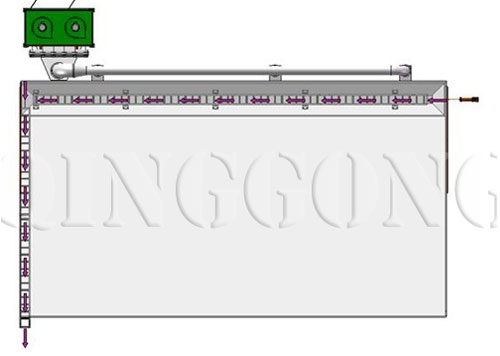

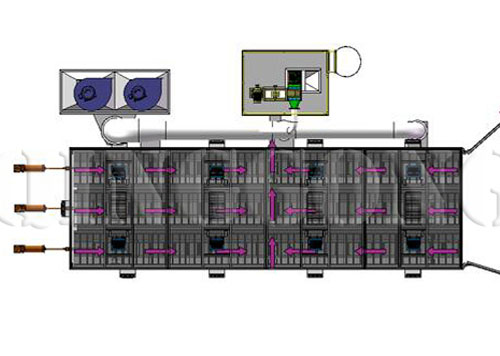

Full Floor Partial Reclaim System

Full Floor Partial Reclaim System

The full-floor reclaim system utilizes multiple screw assemblies or scraper assemblies to create a fully automatic, high volume abrasive reclaim system where 100% of the abrasive blast media is returned to the separator system during the blasting operation. This allows for a faster reclaim as well as full recycling of the abrasive media, saving your blasting operation both time and money.

The Full Floor Reclaim System allows for the maximum efficiency of your abrasive blast system. This abrasive blast reclaim system is well suited for pass-thru and/or high production requirements.

The dust collector is one of the most important components of the sand blasting booth. QINGGONG MACHINERY’s cartridge dust collector are sized to fit each individual room according to room size, parts being blasted, amount of dust from the blast media and airflow.

Advantages:

1. Fast, simple and safe cartridge replacement

Cartridge replacement is performed outside the dust collector and requires no tools. This eliminates the need to work within a confined space and allows the worker to access the cartridge without getting dirty.

2. Continuous operation

The cartridge dust collector does not have to be stopped in order to remove and clean dust particles from its filters.

3. Economical

The cartridge dust collector is an economical choice because it requires minimal maintenance: only periodic cartridge replacement is necessary.

Steel shot blasting is the most widely used process for cleaning, stripping and improving a metal surface. The grade or size of the steel shot will determine the ultimate finish achieved on the surface of the metal. The round ball shape of the steel shot produces a clean, smooth and polished surface through a peening action created by the acceleration of the shot.

A smaller steel shot will result in a smoother and more polished surface. A larger shot will clean more aggressively but produce a rougher surface.

The sand blasting booth can be used for various steel shot.

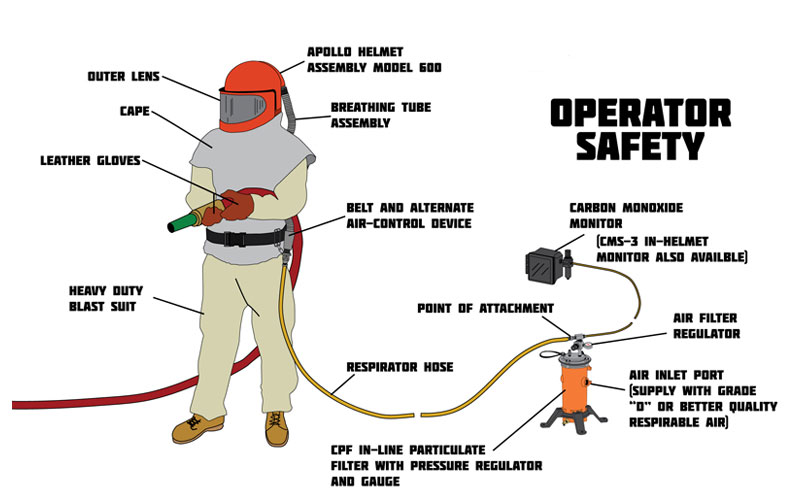

This picture gives clear instructions for sandblasting safety. For more information, you may check the pdf of safety operation manual.

Get Your Project Started with Qinggong Machinery

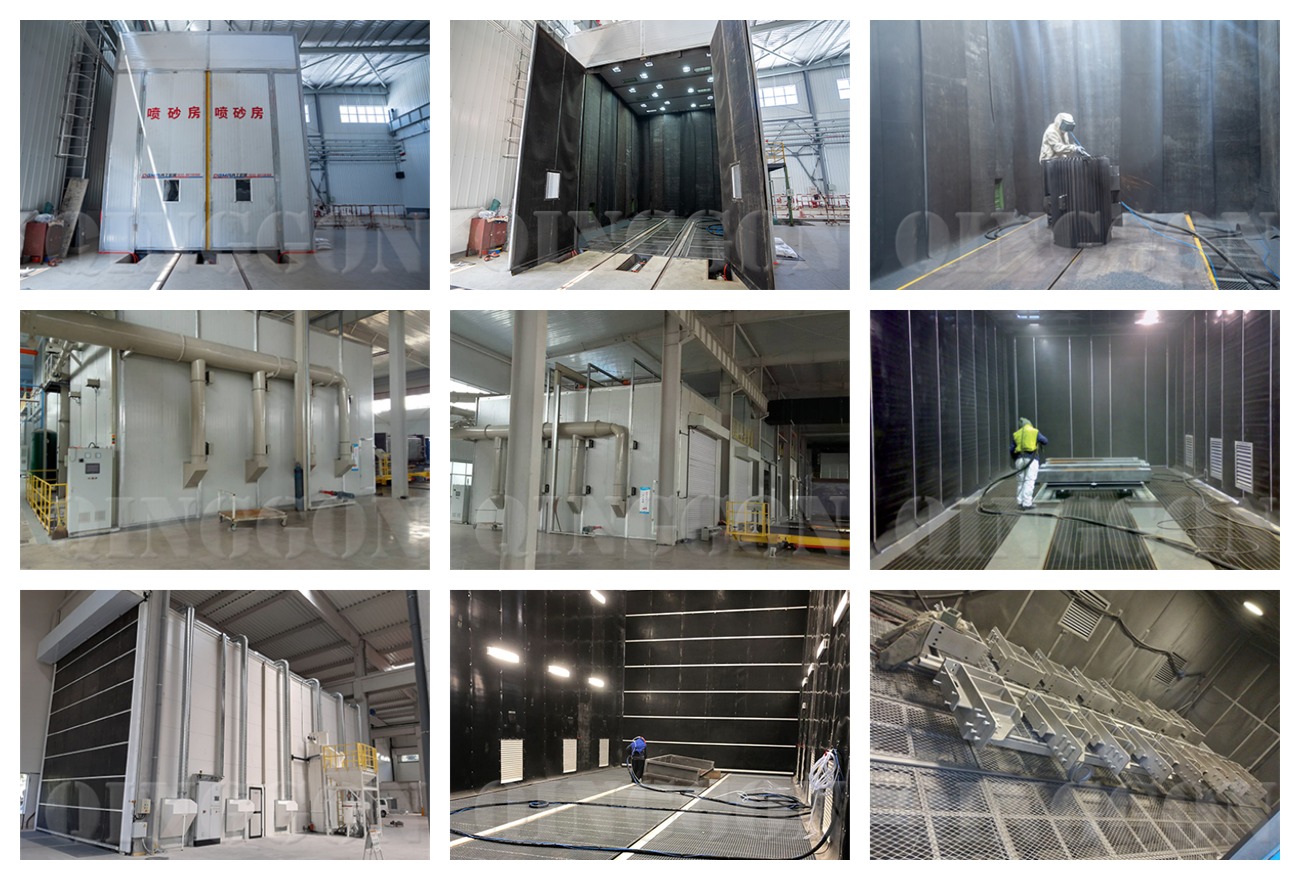

SANDBLASTING ROOM CASE SHOW

Sandblasting Room Delivery to Australia

Sandblasting Room Delivery to Australia

Sandblasting room in Russia

Sandblasting room in Russia

Sandblasting room in Australia

Sandblasting room in Australia