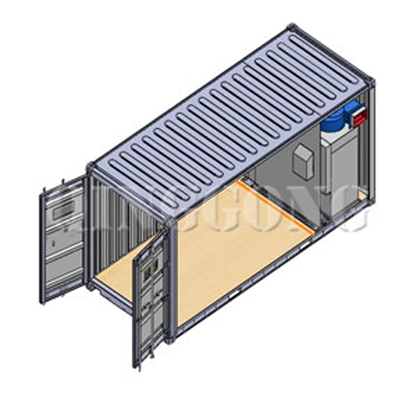

Qinggong Machinery have shipped a set of mesh wire shot blasting machine to Singapore. This machine opening size is 1200mm wide and 500mm height, with 8 units shot blasting turbines so that is can clean the workpiece without dead angle. Because of the customer used to clean the template, it will have concrete block on the workpiece surface and with high cleaning requirements. So our engineering team design the machine with 3 level dust collector, including settlement, cyclone and cartridge filter to achieve high cleaning efficiency and protect the cartridge filter not damage by the concrete.

The wire mesh shot blasting machine is the machine that have high volume production and cost effective performance for deburring, removing, descaling, deflashing or etching. This machine are versatile and allow for efficient shot blasting coverage. Different from drum type shot blasting machine, it suitable for medium and large castings, heat-treated parts, automotive wheels, ferrous and non-ferrous metal castings, welding parts, fabrications and more. Especially for the shot blasting process has special requirements of iron and aluminum alloy flat, thin wall and fragile parts of the shot blasting.

The heart of the mesh wire shot blasting machine are the circulating mesh wire screen coveyor belt made of manganese steel wire and the blasting turbines driven by different powers. The layout of the blasting turbines adopt 3D dynamic simulation design to ensure the best shot blasting angle and distance.

The blasting chamber is made of high strength steel plate and profile steel to ensure sufficient strength and stiffness of the machine. In the hot zone we used the easily replaceable high manganese steel plate, which hardness can up to HRC60. In the chamber also have the third plate cover on the gap of the other two plates, so that eliminates the possiblility of high speed steel shot directly damage the blasting chamber. High impact toughness can make full of the reflection of blasting to continue to clean the surface of the workpiece, so as to greatly improve the cleaning efficiency and quality. In the bottom of the blasting chamber used the high chromium wear-resistant saddle plate to ensure that when the used abrasive entered into the recovery system to prevent them fall into the screw conveyor and make damage.

About the shot blasting machine Qinggong Machinery is the most professional manufacturer, if you want to know more about the machine please contact me. We will give you the cost-effective solutions for you.

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro