Some manufacturers have purchased shot blasting machines. After using it for a period of time, they found that the thrown parts did not achieve the expected results. In the beginning, some manufacturers thought it was a problem with the quality of the shot blasting machine, but after the later investigation, it was not a problem with the equipment. , the steel shots and steel grit purchased by some manufacturers are correct to use, but the workpieces produced by themselves are not very effective.

General steel shot: the hardness is HRC40-50 for processing hard metals, which can increase the hardness to HRC57-62, and the service life is several times that of cast iron shots.

Cast iron shot: The hardness is HRC58-65. It is easy to break when hit on the workpiece, and it is mainly used in places with high spray strength.

The compactness of molding sand can be expressed by hardness, bulk density, and sand mold strength. Hardness is the value read by directly measuring the surface of the sand with a sand hardness tester.

Generally, the surface hardness of sand mold is 60-80 units, and the high-pressure molding can reach more than 90 units.

Some reasons for the poor cleaning effect And coping methods

1. The projectile fan-shaped projection angle is not aligned with the workpiece to be cleaned.

Adjust the position of the blast wheel control cage window so that the abrasive can be projected onto the shotblast spares

2. Insufficient abrasive, prolonged cleaning time

Add steel sand and check the steel sand cycles system

3. The abrasive impure is mixed into the impurity to block the abrasive channel

To remove impurities in the abrasive, the abrasive should be sieved before adding.

4. Excessive wear of blast wheel control cage outlet

Check the control cage regularly and replace it in time if it is found to be severely worn

5. Distributor wear is too large to reduce the efficiency of the nine

Check the distributor regularly and replace it in time

6. The abrasive contains waste sand and too much dust

Dredge the dust collector system pipes in time to avoid pipe blockage, which will greatly reduce the effect of the abrasive separation, the bucket elevator belt is slack, the distributor is lower than the rated speed, and the shot blasting system and abrasive kinetic energy are reduced.

The relationship between abrasive hardness and cleaning effect

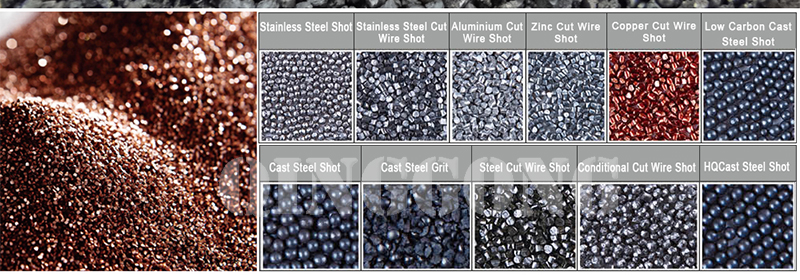

We know that the treatment effect of the workpiece is not only related to the hardness of the abrasive, but also to the model of the abrasive and the shape of the abrasive. For example, an abrasive with an irregular surface has higher rust removal efficiency than a circular abrasive, but the surface is rougher. Therefore, when consumers choose abrasive for rust removal, they must start with the model, hardness, specification, and shape of the abrasive according to their actual needs.

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro