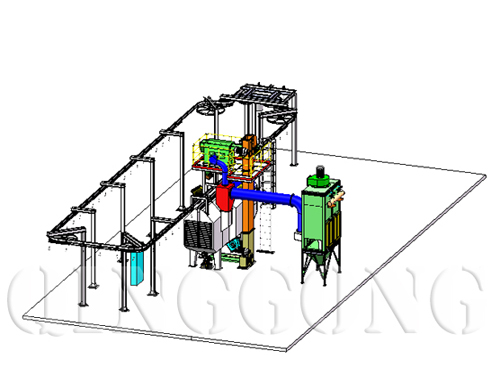

The tumble belt shot blasting machine is a new type of special shot blasting equipment designed according to user requirements. It is used for cleaning and strengthening castings and forgings, small round springs, bearings and other workpieces.

Machine application

This equipment has larger shot blasting capacity, better sealing, and greatly improved cleaning effect, production efficiency and dust removal effect. The use of rolled Mn13 chamber body guards reduces maintenance costs by about 60 %. Through shot blasting cleaning and strengthening, not only can the rust, oxide scale, casting sand on the surface of the workpiece be removed, but also the internal stress of the workpiece can be reduced, and the fatigue strength of the workpiece can be improved. This belt shot blasting machine can be used as a stand-alone machine or by wiring, and has a high cleaning efficiency.

working process

Interlock start-feeding-enter the shot blasting room-close the door-start the blast turbine-roll the workpiece-open the door of the shot material-turn the workpiece over the shot material-close the door of the shot material-open the door-the workpiece exit the shot blasting room-convey by the conveyor- The loading and unloading can simultaneously carry out the shot cycle.

working principle

After adding a specified number of workpieces in the blasting chamber, the door is closed, the machine is started, and the workpiece is driven by the tumble belt to start turning. At the same time, the steel shot thrown by the blasting turbine at high speed forms a fan-shaped beam, which hits the surface of the workpiece evenly, so as to achieve the cleaning. purpose. The thrown steel shots and sand particles flow into the screw conveyor at the bottom from the small holes on the crawler belt, and are sent into the elevator through the screw conveyor, and the elevator is lifted into the separator for separation. The dust-containing gas is sucked by the fan and sent to the dust collector to be filtered, and then becomes clean air and discharged into the atmosphere. The dust is blown back by the air into the dust box at the bottom of the dust collector, and the user can clean it regularly. The waste sand flows out from the waste pipe and can be reused by the user. The shot-sand mixture is recycled into the chamber by the recycling pipe, and reused after the separator is separated. The layout of the blasting turbine is dynamically simulated by the computer, and all the angles and positions of the layout are determined by the computer design. On the basis of taking care of all the workpieces that need to be cleaned, the empty throwing of steel shots is minimized, thereby maximizing the utilization rate of steel shots and reducing the wear of the protective plate in the cleaning room.

Machine operation

All the operators of this shot blasting machine must have a comprehensive understanding of this manual and the working principle, performance, operation method, lubrication and other aspects of this machine before they can operate;

Put the steel shot (200kg) into the chamber one after another, then put the workpiece into it, close the feeding door, and prepare to drive;

Start the dust collector fan;

Start by pressing the buttons in turn: hoist, blasting turbine, pill supply gate, and start cleaning. After the cleaning is completed, turn off the buttons in turn: the pill supply gate, blasting turbine, hoist, dust collector fan, and then start the rapping motor to clean the dust, and the rapping will stop after a certain period of time;

After the blasting turbine is completely stopped, open the feeding door and lift the tooling and workpiece out;

In case of emergency, you can press the emergency stop button and the machine will stop working immediately;

After all the work is completed, the dust collector should be turned off in time;

In the ventilation and dust removal system, there are two butterfly valves (see the dust removal system diagram). Adjust the two butterfly valves according to the situation to get a good separation effect;

Adjustment of the directional sleeve of the blasting turbine: The adjustment of the directional sleeve can be adjusted with reference to the schematic diagram shown in Figure 4. During use, due to the wear of the directional sleeve, the spread angle of the steel shot increases, resulting in accelerated wear of the blasting turbine and other guard plates in the cleaning chamber. . Therefore, when the wear of the directional sleeve exceeds 10 mm, a new one should be replaced (the angle between the opening direction and the horizontal square line is 45°).

Precautions

The dust in the dust box under the dust collector should be removed regularly to prevent blocking the dust exhaust pipe and affecting the dust removal effect;

The debris under the screen in the bottom of the cleaning room and the separator funnel should be cleaned frequently;

The steel shot around the equipment should be cleaned frequently to prevent slippage and hurt people;

The crawler belt and hoist belt in the cleaning room should be checked frequently for deviations to avoid damage to the belt;

It is forbidden to open the charging door when the blasting turbine is not completely stopped to prevent accidents.

Machine maintenance

After each work shift, the industrial shotblaster should be cleaned again;

The guard plate in the cleaning room, the directional sleeve in the blasting turbine, the blasting wheel and other wear parts should be checked frequently. If the wear is serious, they should be replaced immediately;

Lubricate regularly as required, and check whether the machine is flexible;

Regularly check the transmission parts, clean the parts, and replace the worn parts;

When the machine is inspected and maintained, the power must be cut off to avoid accidents;

The wear-resistant guard plate of the cleaning room can be replaced regularly according to the wear condition. When replacing the guard plates, the installation gap between the guard plates should be controlled within 2 mm.

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro