Choosing suitable abrasive is an important for shot blasting machine sandblasting room, if the abrasive is not suitable for equipment, it will not only make the equipment damaged, but also lead to the blasting effect is unsatisfactory.

Each different sandblast and shot blast abrasive media material has its own qualities beyond shape, size, hardness and density. Media material selection primarily depends on the surface being prepared or treated, not necessarily on the type of abrasive equipment being used. The blasting media comparison is very significant. And here are the common abrasive media materials you'll find in sandblasting and shot blasting operations:

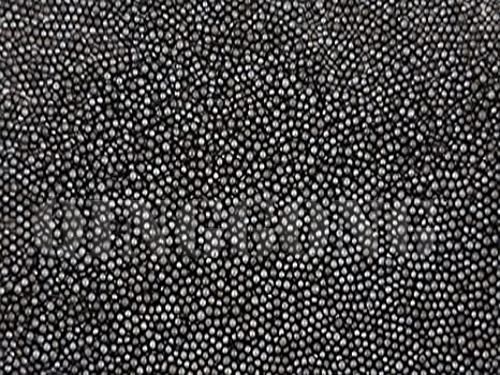

Steel shot and steel grit: For heavy-duty jobs, nothing beats steel abrasives. Steel shot is round while steel grit has an angular shape.

Glass beads: Soft surfaces require a gentle abrasive. Glass beads made from soda-lime are one of the softest abrasive media materials on the market.

Plastics: Abrasives made from plastic vary in size, shape, hardness and density. Plastic materials include polystyrene and polycarbonate. They're ideally suited for fiberglass treatment.

Sand: Some sandblasting operations still use sand. However, the health hazards outweigh any abrasive advantages. OSHA highly regulates silica sand exposure to workers.

Hardness of steel shot: Steel shot that is too soft cannot produce suitable residual stress, and the impact force of low-hardness steel shot cannot be compensated by increasing the impact time. High hardness steel shot will cause unsatisfactory surface morphology, increase the probability of fragmentation of the steel shot, increase consumption, and wear equipment, increase equipment maintenance costs. Steel shot hardness is high, cleaning speed is fast, but short life consumption is large, so the hardness should be moderate (about hrc40-50 appropriate) use the best effect

The blasting materials for sand blast room, it depends on what kind of material customer need to blast cleaning, this is the first things first for the blasting media' choice, for garnet, glass beads, steel shot, no problem for all of these.

But most industrial shotblaster customer prefer the steel shot, causes it can cycle many more times than the garnet, glass beads, etc.

With 100+ workers, 22 engineers, and a service team of 10, QINGGONG machinery have the capability to meet your requests of shot blasting and sand blasting machines. Welcome to contact us.

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro