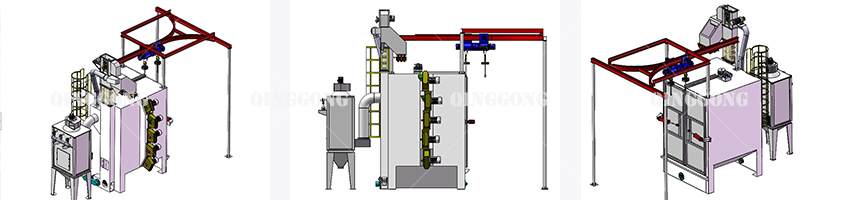

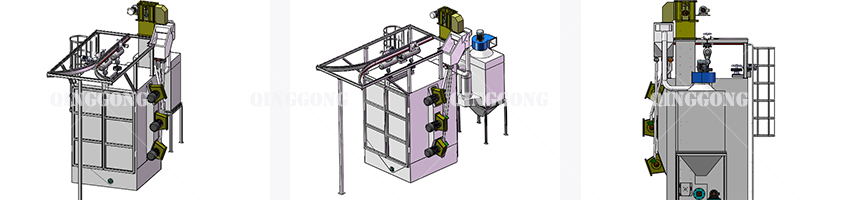

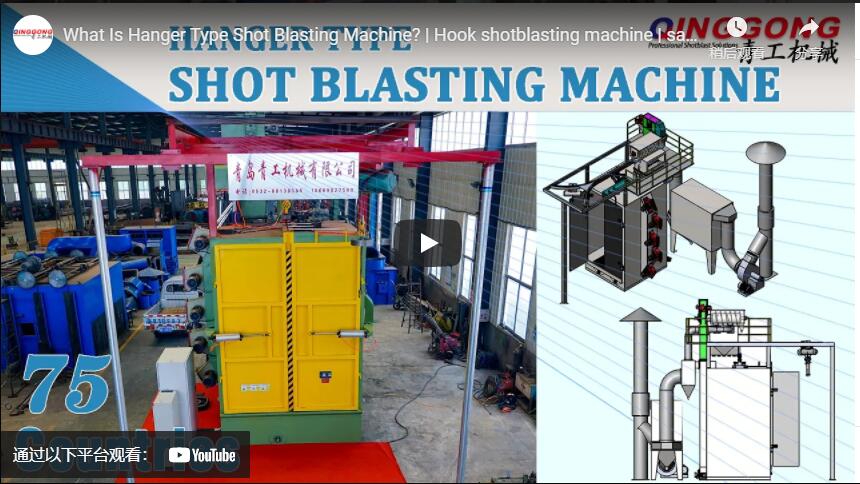

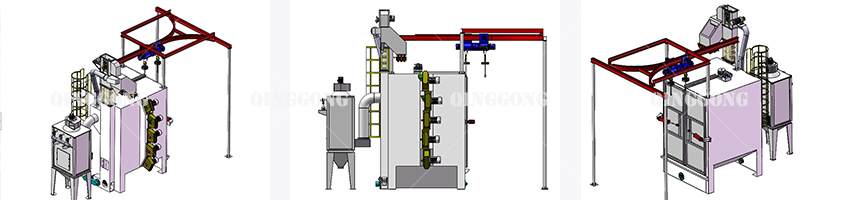

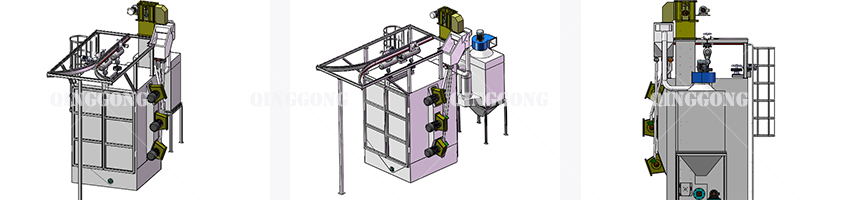

Double hook type shot blasting machine:

| Machine type | QGDH7/12 | QGDH10/16 | QGDH12/18 | QGDH14/22 |

| Max. diameter of workpiece batch(mm) | 700 | 1000

| 1200 | 1400

|

| Max. height of workpiece | 1200

| 1600 | 1800

| 2200 |

| Max. weight of workpiece(kg) | 600

| 800 | 1000 | 2000 |

| No. of wheels Power(kW) | 2*7.5

| 2*11

| 2*15 | 3*15

|

| Foundation pit | NO | NO | NO | NO |

Larger sizes are available, as are a huge range of options. Represented here are the Standard /Stock pre-engineered machines. Please contact us for further information.

Double hook shot blasting machine working principle

Double hook shot blasting machine load the workpiece to be processed on the machine, press the start button and go through a short period of time (usually 5-7 minutes). Double hook type shot blasting machine uses two hooks to load workpieces alternately into the blasting chamber. Use the blast turbines to throw steel shot to the surface of the workpiece to make the surface of the workpiece reach a certain roughness to change the compressive stress of the workpiece to increase its life. After the entire cleaning process is completed and all dust and residual shots are removed.

Double hook type shot blasting machine advantage:

The international advanced cantilever centrifugal blast turbines with large shot blasting volume and high shot speed is adopted to improve the cleaning rate and cleaning quality.

All drawings of the simulated projectile diagram and shot blasting machine are drawn by computer-aided design (CAD) and the selection and layout of the blast turbine are more reasonable.

The use of a pit-free structure not only saves the construction cost and time of the pit foundation, but also solves the problem of rust and agglomeration of shot sand in the bucket elevator caused by the user due to the water in the pit. The hook has the functions of lifting, running and indoor rotation.

The blasting chamber adopts high chromium guard plate, the service life is greatly improved and the appearance is beautiful and easy to replace.

The double hook shot blasting machine suitable to lift workpieces with a weight of less than 3 tons. Double hook shot blasting machine has large volume, high cleaning efficiency, large effective room space, compact structure, no pit form, no special requirements for the shape and structure of the cleaning workpiece and one machine can be used for multiple purposes.

EN

EN

fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  th

th  pl

pl  ro

ro