Preservation line is made up of blasting, painting and drying parts, can use for steel plate, profiles, pipes and channels. Preservation lines are ideal when there is a lengthy manufacturing or storage time between blasting and final coating.

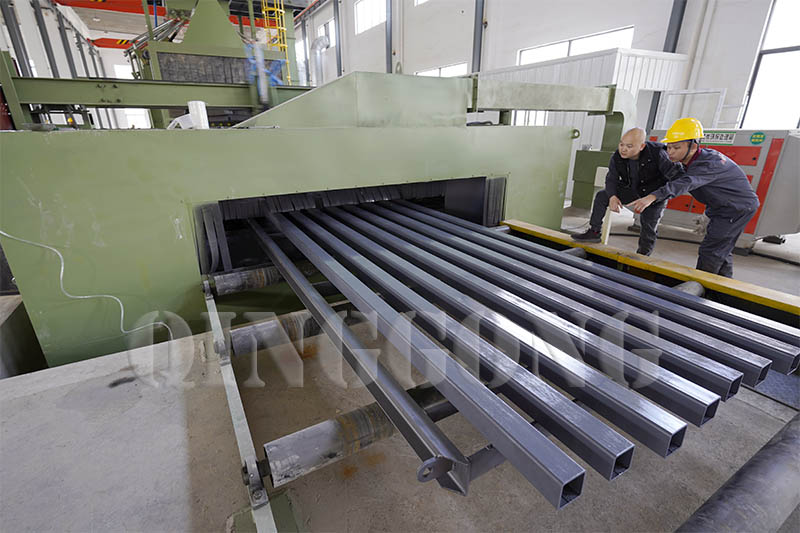

We have made a preservation line for China customer, used this machine to blast steel plate, steel pipes and steel structure.

The workpiece reaches the inlet of the chamber, the photoelectric detection system will send a signal to the computer, counter start to work to calculate the distance between workpiece with the blasting chamber. When workpiece into the blasting chamber, blasting turbines start to do blasting work. The blast turbines will automatically stop after the workpiece is out of the blasting zone. That will avoid the blasting turbines working when the blasting chamber is without parts, extend the service time of the blasting chamber, let energy cost be saved max. 30%. About the blast wheels, the abrasive utilization rate increased to 99%, improving efficiency by 30%. The maximum thickness of the blast wheel shell can reach 70mm, a better sealing effect. The blast wheel bottom has to cushion rubber, which can reduce vibration. The elevator adopts a flat belt drive hopper, the lip of the hopper adopts a wear-resistant design, the shell can be disassembled in sections, and there are maintenance and inspection windows for easy maintenance. There is a tensioning device on the upper part of the hoist, which can easily adjust the belt tightness. Anti-reverse mechanism to prevent the belt from reversing due to power outages and other reasons. The abrasive flowing in from the bucket elevator is pushed apart by the conveying screw to be evenly distributed, and finally reaches the separator, forming a waterfall-shaped abrasive flow curtain. Under the full curtain state, the principle of gravity winnowing is used to effectively separate the projectiles from the metal oxide scale fragments, broken projectiles and dust. The surface shot blasting machine with PLC, touch screen, indicator light and others. In automatic painting, the thickness of the paint film can be adjusted. Configure a different numbers of guns according to workpiece size.

As one of the best sand blasting machine manufacturers, We are very professional in shot blasting and priming line, please feel free to contact us if you are interested.