Metal abrasives include steel shot, steel grit, iron shot, iron sand, stainless steel shot, stainless steel sand, steel wire cut shot, and stainless steel wire cut shot, etc.

Each type of shot blasting machine equipment requires different types of abrasives. If the final type of abrasive needs to be determined, it also depends on what kind of workpiece the shot blasting machine is blasting and the desired shot blasting effect. The size of the workpiece is different, and the abrasive used is also different, so the specific type of abrasive used depends on the situation.

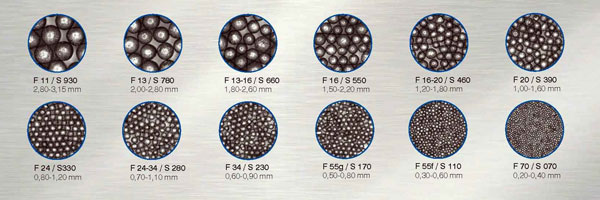

The larger the abrasive diameter, the higher the surface roughness of the workpiece, but the shot blasting efficiency is also high; the abrasive diameter should be selected according to the surface roughness of the part. The shot blasting efficiency of other irregularly shaped steel shots or cut wire shots is higher than that of spherical shots, but the surface roughness is also higher.

Choose the abrasive with a moderate hardness to achieve a good application effect. Suitable abrasive hardness and excellent resilience, so that the abrasive can be projected to every part of the shot blasting machine chamber, and then reduce the blasting time.