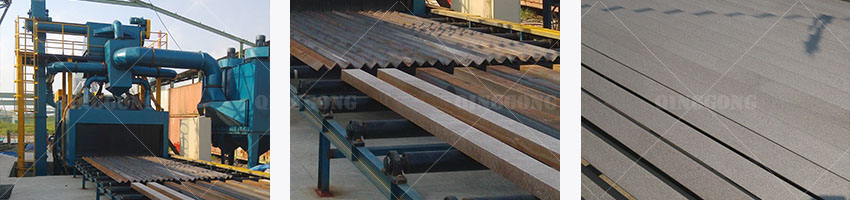

Profile Steel shot blasting machine is the most efficient and the most effective process to remove all forms of rust and corrosion materials fromsteel profile prior to painting or coating. We are professional shot blasting machine supplier.

Profile Steel shot blasting machine is the most efficient and the most effective process to remove all forms of rust and corrosion materials fromsteel profile prior to painting or coating. We are professional shot blasting machine supplier.

Type | unit | QGB600 | QGB1000G | QGB1500 | QGB2000 | QGB2500 | QGB3000 |

Effective blasting width | mm | 600 | 1000 | 1500 | 2000 | 2500 | 3000 |

Dimension of entrance(W×H) | mm | 800×550 | 1200×550 | 1700×550 | 2200×550 | 2700×550 | 3200×550 |

Work speed to achieve a cleaning of Sa2.5 ISO8501 | m/min | 0.5~3 | 0.5~3 | 0.5~3 | 0.5~3 | 0.5~3 | 0.5~3 |

Number of wheels×power | kW | 4×7.5/11 | 4×11/15 | 4×11/15 | 6×11/15 | 8×11/15 | 8×11/15 |

Wheel optional | kW | — | — | — | 4×15 | 6×15/18.5 | 6×15/18.5 |

Abrasive initial filling capacity | kg | 2000 | 4000 | 4000 | 4500 | 6000 | 6000 |

Processed length of work piece | mm | 1200~12000 | 1200~6000 | 1200~12000 | 3000~12000 | 2400~12000 | 3000~18000 |

Foundation pit required | No | No | No | Yes | Yes | Yes |

Technical support:

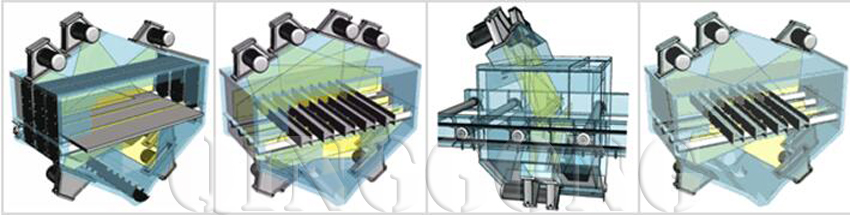

1. The engineer team use 3-D dynamic simulation design blast turbines layout to ensure that the steel shot ray can cover the surface of the steel structure 360 degrees.

2. The equipment adopt pneumatic control abrasive distribution system, which eliminate the blast wheel idling and injuring workers.

3. The machine adopt environment friendly high efficiency cartridge filter, dust collecting efficiency reach to 99.9%

4. The machine with limit switch on access door, that protect people in any case they open the door, the blast turbines will stop according.

5. Six layers protection curtain for protection the shot balls spatter out during blasting.

6. The machine with sand-guide channel at the outlet of the equipment, and the steel shot on the steel structure can be poured out in the sand-guide channel, and then enter the recovery system.

7. The steel structure shot blasting machine use high effective abrasive recovery system. A longitudinal screw conveyor to reclaim the used blasting media and contaminants into the crosswise screw conveyor, then into the bucket elevator and abrasive residue separator, and then the cleaned abrasive get into the storage hopper to recycle, the residual will get out of the recycle system from the air wash cleaner system.

Abrasive residue separator

Our patented abrasive cleaner is applied for recycling shot/grit, which is to ensures high quality blasted surface and minimal abrasive shot. As the abrasive is so durable it is able to be recycled hundreds of times, resulting in an extremely low abrasive breakdown rate.

Critical to achieving this efficiency is the effectiveness of the abrasive recycling plant. Poorly designed or manufactured abrasive recycling systems will not correctly recycle the abrasive and are unable to maintain the correct abrasive working mix.

Our patented abrasive separator consists of an extended rotary separator drum that will totally remove all big clumps including big wast, scrap and paint chips etc. The abrasive is then fed through a gravity air wash separator where all dust, degraded abrasive and waste is drawn out of the good abrasive by an air current.

Only good, correctly sized abrasive is fed back to the abrasive storage hopper and blast pots for recycling.

Our patented abrasive cleaner ensures maximum recyling rates of the abrasive and high quality surface finishing is achieved.

Leave us Message